How to turn chicken manure compost into granules for 5 tonnellate all'ora?

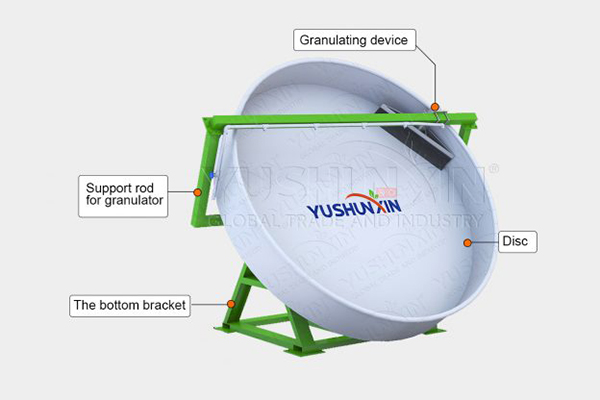

The customer from Honduras told us that there are 50 tons of chicken manure compost generated in his farms now. And he planned to make the composted chicken manure pelletizer work for 10 hours a days. COSÌ, we recommend the SXYZ-3600 Pellettatrice a dischi to chicken poop compost granulation process.

Per prima cosa, it can produce 4-6 tons of organic fertilizer granules from chicken manure compost per hour. This can fully meet your requirements of granulating 50 tons of chicken manure compost per day. Per un altro, with disc pelletizer, you can choose to make 1-8 mm granular chicken manure fertilizer freely. Allo stesso tempo, the granulation rate can reach 93%.

What other equipment is needed in the 5 TPH chicken manure compost granulation plan?

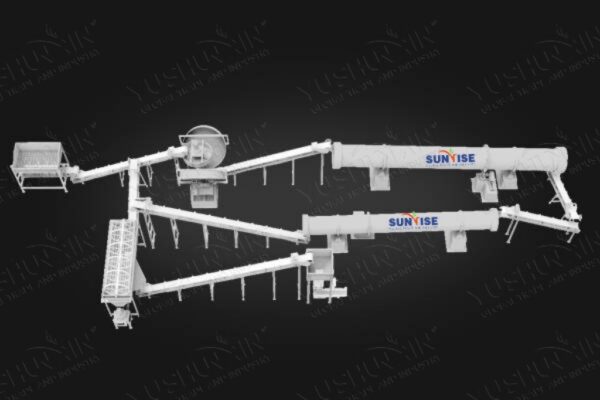

Because the pan pellet machine adopts wet granulation method in chicken manure granules making, it needs fertilizer equipment as follows. Compost feeder, vertical crusher, SXYZ-3600 disc pelletizer, SXGS-1540 compost screener, SXHG-1616 fertilizer dryer and cooler, and single-bucket packing equipment.

How to make 3mm size chicken manure compost pellets by disc granulator?

In terms of produced chicken manure fertilizer pellets, the customer from Honduras requires a 3 mm size and round ball shape. Primo, disc pellet machine can fully meet your needs of round ball compost pellet making from broil waste. Inoltre, for 3 mm size chicken poop fertilizer granules manufacturing, you only need to do steps.

Adjust the disc tilting angle to 40°- 60°

In the process of turning chicken poop compost into organic fertilizer pellet, Sharp slope, smaller size; slow slope, bigger granules. Qui, we can offer you disc granulation machine with variable frequency drive (VFD) controlled motor. Which can help you regulate the pan slop angle to prepare quality chicken waste fertilizer easier.

Control moisture of chicken manure compost with 20%-40%

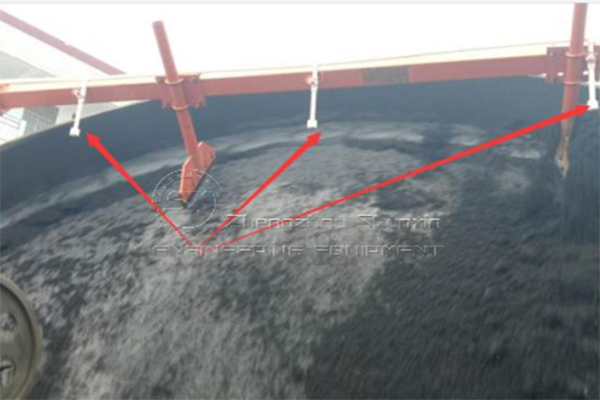

Allo stesso tempo, you need to control the moisture in chicken manure compost granulation process. Generalmente, less water, smaller size; much water, bigger size. Per questo, there is chicken manure pelleting machine with spray line on sale. This is beneficial for control the water content of chicken manure compost granule production.

Can we replace the disc of chicken manure pelletizer with stainless steel material?

In order to prevent chicken manure composting granulation from eroding the disk pelleting equipment, the Honduras client asked about compost granulator material. After know it is Q235 carbon steel, he wanted to replace with a stainless steel chicken manure pelletizer. Per questo, YUSHUNXIN can offer you service of fertilizer equipment customization. Besides spray device adding and stainless steel replacement, we also can adjust the feeder, discharge chute, disc depth, ecc.

What is the quotation of the composted chicken manure pelletizer line?

Then after visit our factory and operational chicken poop compost granulation line, the Honduras customer was very satisfied with the fertilizer machines. However, he needed a precise quote for the 5 t/h chicken manure compost pellet making line. Qui, because of stainless steel material use, spray device adding and discharging chute adjustment, its EXW price is $256,300.

If you need precise price of your own compost granulation line, non esitare a contattarci immediatamente.

The above are details about our communication with the customer about composted chicken manure pellet making in Honduras. Inoltre, we also can offer you customized compost granule making plans. Ad esempio roller press granulation line for dry compost, rotary drum granulating system for large scale compost pellet making, ecc.

Contenuto

Altri casi