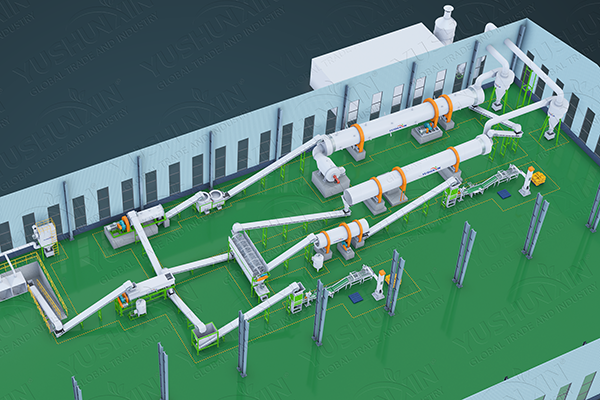

1-30 t/h compost granulating machines for sale in YUSHUNXIN

In order to meet your requirements of turning compost into organic pellet in both small scale and large scale, YUSHUNXIN offers a comprehensive selection of compost granulating machine. They can cater to various scales of compost fertilizer manufacturing, from 1 t/h to 30 t/h.

1-30 t/h Drum pelletizer for industrial organic fertilizer granulation with compost

For large-scale industrial compost pellet making plant setup, we recommend you the rotary drum pelletizer.

Because, it can transforming large quantities of compost into uniform organic fertilizer granules in a short time. It can help you setup a compost fertilizer granulation plant with a 1-30TPH capacity. Namely, 100,000 tons annually.

In addition, to reduce the equipment erosion from fertilizer processing, we especially equip the drum granulator with rubber lining and sticking hitting holes. There is also cuatomized stainless steel rotary drum pelletizer for you,

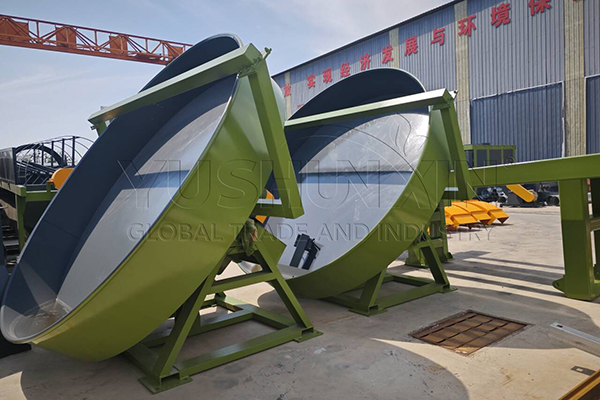

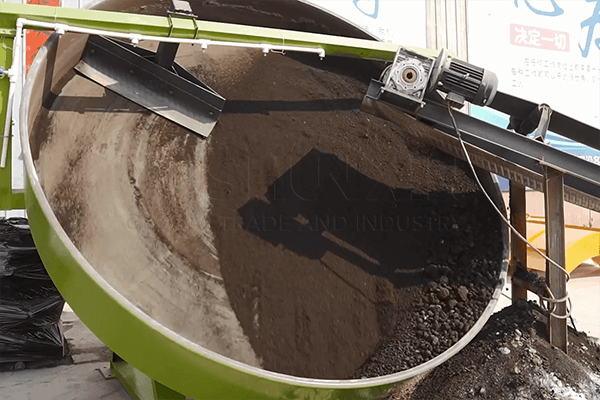

1-6 TPH Disc pellet machine of 93% fertilizer granulation rate

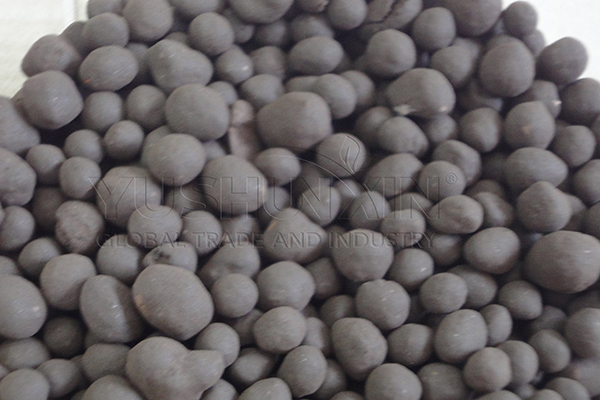

However, for these who more focus on the granulation rate of your organic fertilizer pellets making project, the disc pellet machine is the right compost granulating machine for you.

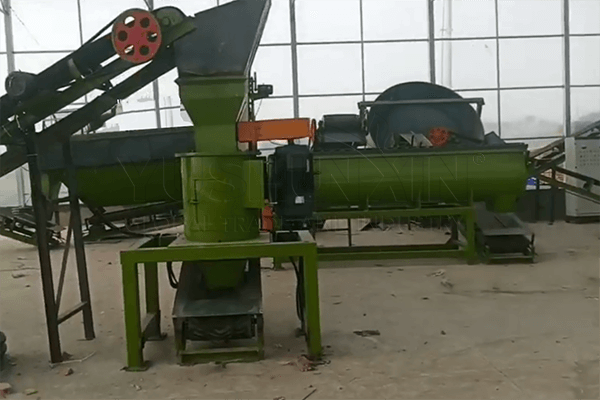

1-8 TPH new type organic fertilizer granulator for hard pellets making

In addition, if you purse a high granulation rate and hard pellets making in your organic fertilizer production project, there is also new type organic compost granulator for you.

The machine makes use of friction between stirring teeth and equipment wall to enforce compost powder convert into organic fertilizer granules. In this way, the granulation rate of compost pellet making can reach 97% and the granulated compost hardness is about 15-20 N.

How about the capacity of the organic fertilizer granulator of compost? 1-8 t/h, which can fully meet your needs to small-medium compost organic fertilizer granules manufacturing.

5–8 TPH rotary drum churning granulator with 95% compost granulation rate

Besides, for 5-8 TPH organic fertilizer pellet making plant setup with high granulation rate, there is also rotary drum churning pelletizer for you.

It combines the structure of a rotary drum with internal stirring teeth, which enhances mixing, granulation, and polishing in one step. Therefore, you can greatly improves the roundness and strength during organic fertilizer pellet making, while maintaining a high granulation rate above 95%.

| Equipment | Capacity (t/h) | Granule Size (mm) | Granulation Rate | Feeding Moisture | Equipment Material |

|---|---|---|---|---|---|

|

Rotary Drum Granulator |

1-30 | 3-6 | 90% | 20%-40% |

Carbon steel Q235 + rubber lining |

|

Disc Granulator |

1-6 |

1-8 | 93% | 20%-40% |

Carbon steel Q235 |

|

New Type Granulator |

1-8 |

2-5 |

95% |

20%-40% |

Carbon steel Q235 + Manganese steel |

| Rotary churning granulator | 5-8 | 2-6 | 95% | 20%-40% | Carbon steel Q235 + Manganese steel |

How to make organic fertilizer pellets from dried compost quickly?

Can we make dried manure into compost pellets directly? Of course. You can choose to buy our dry granulation machine for compost pelleting. It mainly makes use of roller extrusion to press compost powder into fertilizer granules. So, there is nearly no water involved. What’s more, only needs one squeezing, it can complete the granulation of organic composting. Therefore, you can produce granulated compost fertilizer quickly. For this, we design 2 types dry compost granulation machines for your choice. Double roller granulator and flat die mill. The former has a capacity of 1-4 t/h and prepare flat ball compost pellets for you; while the latter only make 1-1.5 tons of compost pellets per hour, with column shape.

Can we make round ball compost pellets with dry granulation equipment?

It is dispensable. On the one hand, the compost pellet produced from disc and drum granulator will pulverize under the action of high speed rotating. On the other hand, the granulated compost from the above the round ball compost pellet machines can fully meet your requirements.

| Equipment | Capacity (T/H) | Granule Size (mm) | Granulation rate | Feed Moisture | Equipment Material |

|---|---|---|---|---|---|

| Double roller granulator | 1-4 | 3-10 | 95% | <15% | Carbon steel Q235 + 20GrMoTi |

| Flat die pellet mill | 1-2.5 | 1-10 | 95% | <15% | Carbon steel Q235 + 20GrMoTi |

Top 3 FAQ about compost pellet making machine from granular fertilizer manufacturers

Besides the types, there are many other aspects you need to pay attention to when buy compost granulating equipment. For example,

How much is the compost granulating machine price?

The cost of a compost granulating machine can vary widely depending on several factors. Such as its capacity, types, construction materials, manufacturer, and additional features. Typically, the compost granulating equipment prices range from a few thousand dollars to over $70,000 USD. As a reliable fertilizer equipment manufacturer of compost organic fertilizer granulation, YUSHUNXIN can offer you an economical factory price.

For the most precise pricing of compost pellet machine you need, Welcome to contact us directly.

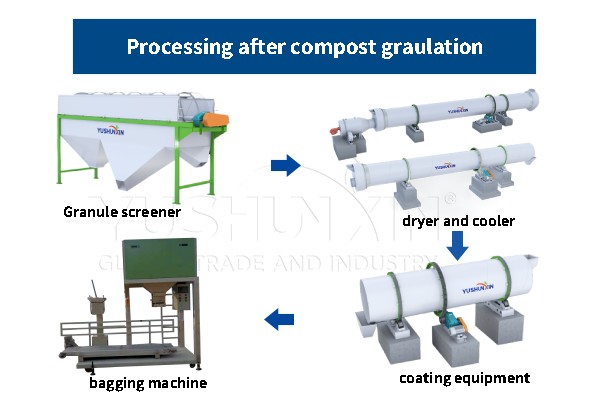

Do we need to dry or crush the compost before or after organic fertilizer granulation?

To produce high-quality commercial organic fertilizer pellets from compost, it’s essential to properly process the material both before and after granulation. This ensures optimal compost granule formation, uniformity, and overall fertilizer effectiveness.

4 steps of pre-processing of compost material before granulation

To produce high-quality commercial organic fertilizer pellets from compost, it’s essential to properly process the material both before and after granulation. This ensures optimal compost granule formation, uniformity, and overall fertilizer effectiveness.

Together, these machines establish a robust production line for creating high-quality organic fertilizer granules from compost on a commercial scale.

Can you offer me some recent projects of compost granule making for reference?

Of course. Over past 20 years, we have helped many fertilizer manufacturers start their compost granulation projects and granular organic fertilizer production plants. They are located in all the worlds. Such as 200000 birds chicken farm waste management in colombia, 30 TPD composted cow dung granulation in kenya, 30000 tons annual biogas digestate fertilizer granulation plant Setup in Germany, etc.

In addition, in terms of material, we also design customized compost granulation plans. Including cow dung compost pellet system, chicken manure compost granulation line, biochar fertilizer granulator system, etc. Come to see them now!

recently granulated compost solutions