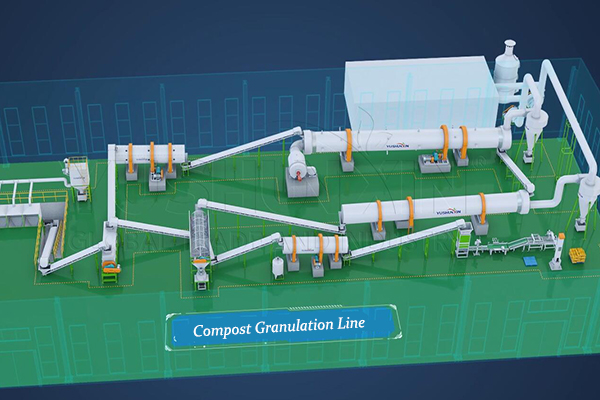

What is the general granulating rate of compost pellet machine?

For producing 3-6 mm organic compost granules, the granulating rate of YUSUNXIN compost pellet making machines generally ranges between 90% to 97%. The specific compost granulation rate varies with design.

Disc pelletizer – 93%

Because of economical price and small space occupation, disc granulator is popular with compost fertilizer granulation plants. In addition, high granulation rate is also an important reason. The machine mainly adopts wet granulation method, which use liquid as binder. So, its organic compost granulating rate can reach to 93%.

Rotary drum granulator – 90%

Rotary drum granulator is the common choice for mass compost granule production. The machine also employ the wet granulation method. But because of large amount of compost material processing, its granulating rate is 90%. Is there method to improve it? Of course. You can choose to add a pan pellet equipment after drum granulation of composted organic fertilizer.

Double roller press machine – 95%

As for the double roller granulator for dry compost pellet making, the granulation rate can reach to 95%. Why? The dry granulation equipment work to make granular compost by physical extrusion force between rollers instead of natural rotation. Therefore, the compost powder can form into organic fertilizer granules easier.

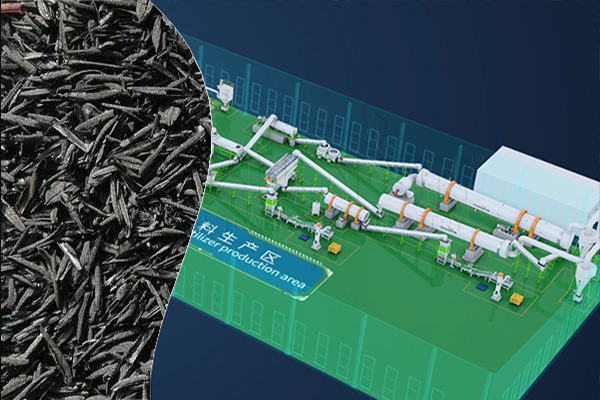

New type organic fertilizer granulator – 97%

And the new type organic fertilizer granulator combine the two method – wet granulation and stirring teeth mechanical force assist. This is the reason why it has a higher granulation rate than the above three compost pellet machines. It is 97%.

What other factors affect the organic compost granulating rate for 3-6mm granules?

Besides compost pellet making machine choosing, you also can improve the organic compost granulating rate for 3-6mm granules by many ways.

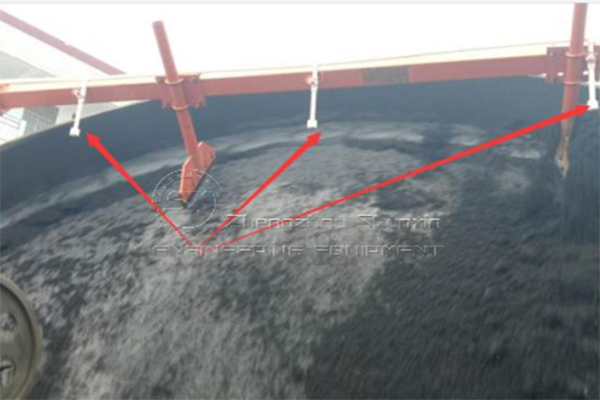

Compost Raw Material Quality

Adding Binding Agents during the compost pellet making

Adding binders can improve the granulation rate for 3-6mm granules. Because this helps compost powder particles to adhere more effectively. For this, the commonly used fertilizer granulation binders contain water, bentonite, humus, etc.

If you still have other requirements for granulated compost making, welcome to contact us immediately. YUSHUNXIN will offer you the best solutions according to your actual conditions.