Haut 3 solutions pour la fabrication de granulés d'engrais digestat

Lors de la fabrication de granulés d'engrais pour digestat de biogaz à partir de compost, il y a 3 solutions recommandées par la plupart des fabricants d’engrais. Ils sont spécialement conçus pour la fabrication de granulés d'engrais digestat à l'échelle industrielle., taux de granulation élevé et matière sèche respectivement.

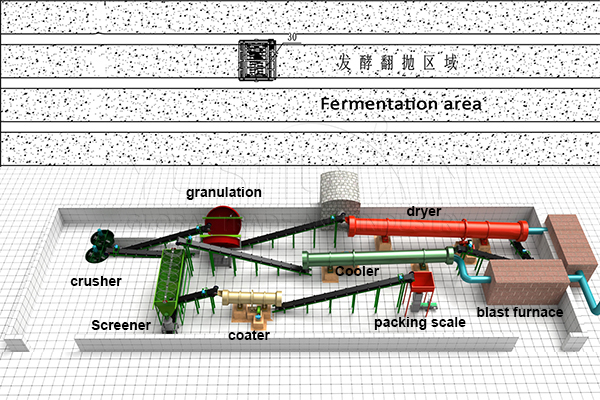

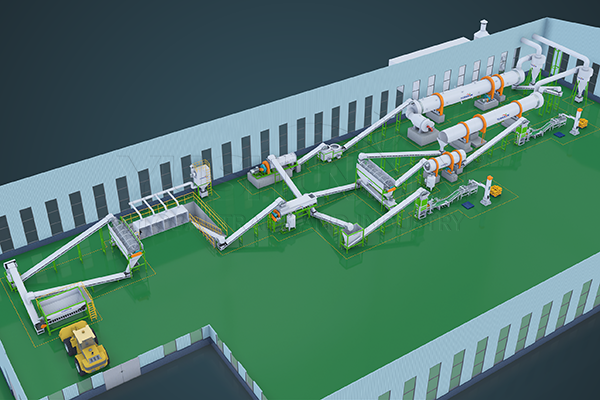

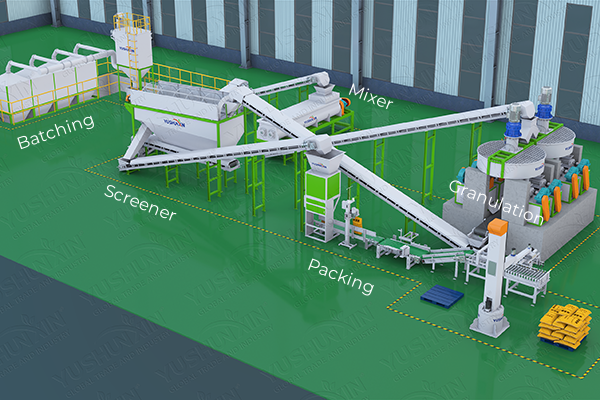

Installation d'une usine de granulation d'engrais de digestat industriel

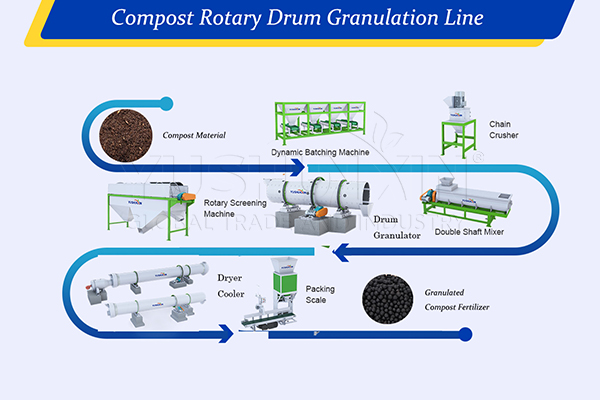

En général, pour la granulation d'engrais de biogaz industriel, le système de pellets à tambour rotatif c'est le top 1 choix parmi les installations de biogaz. Parce que, cette méthode est réputée pour préparer à grande échelle des granulés d'engrais issus de déchets de biogaz. Allant de 1t/h à 30 rendement t/h. En plus, il est doté d'un revêtement en caoutchouc supplémentaire pour la résistance à l'érosion et d'un système de pulvérisation pour ajouter de l'eau ou du liant afin d'accélérer la granulation des engrais des déchets de biogaz

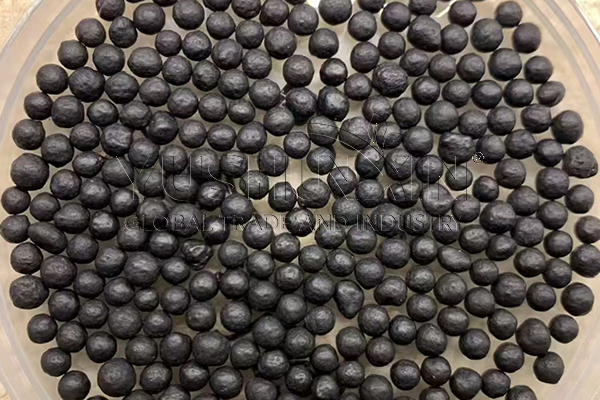

Sur 93% fabrication de granulés d'engrais de résidus de biogaz

Pour la mise en place d'une usine de granulation d'engrais de digestat de biogaz visant une efficacité de granulation élevée, le système de pellets à disque ou nouveau type de plan de granulation d'engrais organique sont d'excellentes options. Le granulateur à disque a un 93% taux de granulation du compost de résidus de biogaz par rotation du disque incliné. Alternativement, le nouveau type de granulateur d'engrais organique utilise une dent d'agitation pour faciliter le taux de conversion. Cela peut améliorer le taux de conversion 95% pendant la poudre de compost pour digérer le processus de granulés d'engrais.

Solution pour la transformation du compost sec de déchets de biogaz en granulés d'engrais

En outre, si votre matériau pour la production d'engrais organiques granulaires est du compost sec de résidus de biogaz, le plan d'extrusion de presse à rouleaux est la meilleure solution économique. Cette technologie consiste à presser le compost sec des déchets de digestat en granulés à l'aide de rouleaux. – presque pas besoin d'eau. De cette façon, il ne nécessite pas de séchage supplémentaire pour la fabrication de granulés d'engrais pour digestat de biogaz.

Ci-dessus 3 Les solutions peuvent répondre pleinement à vos exigences en matière de production d'engrais granulaires de résidus de biogaz dans 1-30 capacité t/h et 1-10 taille en mm par conception raisonnable. Venez dès maintenant obtenir votre propre plan de granulation d'engrais pour digestat de biogaz!

Quel budget est nécessaire pour la fabrication de granulés de compost de digestat de biogaz

Pour choisir la bonne solution pour votre usine de fabrication de granulés d’engrais digestat, le budget est un aspect nécessaire que vous devez prendre en compte.

$100,000 – $550,000 solution

Si vous disposez d'un budget suffisant pour la fabrication de granulés de compost de déchets de biogaz, la solution de granulation avec une machine de granulation à tambour rotatif et un nouveau type de granulateur d'engrais organique. Le système contient généralement des équipements de dosage, écrasement, mélange, granulation, tamisage, séchage, refroidissement, revêtement et emballage. En général, tu dois te préparer $100,000 – $550,000 investissement pour l'achat du système de granulation du compost de digestat.

$50,000 – $250,000 plan d'affaires

Mais, lorsque vous envisagez d'établir une usine de granulés d'engrais pour déchets de biogaz à petite échelle (1-5 ème) et a un budget limité, il est conseillé d'acheter une ligne de granulation à disques ou un système de granulation à rouleaux. Le premier convient à la fabrication de granulés d'engrais organiques à partir de compost de déchets de digestat humide à faible coût.. Le prix $80,000-$250,000 pour 1-5 rendement t/h. Le dernier, comme mentionné ci-dessus, il transforme les résidus de biogaz fermentés en granulés sans séchage. Donc, il s'agit généralement d'un équipement de dosage, broyeur, mixer, granulateur à rouleaux, tamis et balance d'emballage. Et cela nécessite un investissement de seulement $50,000 – $180,000.

Devons-nous utiliser des additifs dans la granulation du compost de déchets de biogaz?

L'incorporation d'additifs dans le processus de granulation des résidus de biogaz est souvent nécessaire pour améliorer la qualité de l'engrais final.. Les additifs peuvent servir à diverses fins, tel que:

Pour faciliter la formation de granulés de déchets de biogaz et améliorer la durabilité. Ici, vous pouvez choisir d'ajouter de l'amidon d'eau, cellulose, sulfonate de lignine, etc.

Augmenter la teneur en éléments nutritifs de l’engrais digestat pour répondre aux besoins agricoles spécifiques. Comme l'urée, KCL, calcium, magnésium, etc.

Le choix des bons additifs dépend des caractéristiques souhaitées des granulés d'engrais de résidus de biogaz que vous souhaitez préparer.. Ici, YUSHUNXIN peut vous proposer un mixeur professionnel et équipement de revêtement pour l'alimentation en additifs avant ou après la granulation du compost.

Pouvons-nous produire des granulés d'engrais organiques à partir de résidus de biogaz avec 70% Humidité?

Généralement, il y a 2 défis liés à la production de granulés d'engrais organiques à partir de résidus de biogaz avec une teneur en humidité de 70%.

D'une part, une teneur élevée en eau entravera la fabrication de granulés d'engrais digestat. D'autre part, les déchets de biogaz frais contiennent diverses substances nocives. Ne t'inquiète pas, YUSHUXIN a des solutions parfaites pour vous. D'abord, c'est un déshydrateur industriel, ce qui peut vous aider à réduire l'humidité des déchets de biogaz à 30% rapidement. Alors, tuer les agents pathogènes, oeufs nuisibles, graines de gazon, etc dans les déchets de digestat, là aussi personnalisé équipement de compostage pour toi.

Pouvez-vous installer la ligne de granulation d'engrais de résidus de biogaz en Allemagne?

Bien sûr. D'abord, Livraison d'équipements d'engrais pour digestat YUSHUNXIN dans le monde entier. Comme l'Allemagne, Nigeria, Kenya, Turquie, Zimbabwe, etc.. En plus, l'installation des machines à engrais, un guidage à distance et sur site que YUSHUNXIN peut offrir en fonction de vos besoins. Nous ferons de notre mieux pour vous aider à démarrer votre production d'engrais à base de résidus de biogaz dès que possible.. Enfin, pour ligne de granulation de résidus de biogaz en Allemagne, il y a une usine établie avec 30000 tonnes/an de production. Il contient des processus allant de la déshydratation des déchets de digestat de biogaz au conditionnement d'engrais granulés.. Le coût total de l'achat de l'équipement est de 153,347 USD. Maintenant, la production de granulés d'engrais commerciaux pour déchets de biogaz fonctionne sans problème pour les clients allemands.

Que vous souhaitiez fabriquer des granulés d'engrais pour digestat de biogaz à partir de compost ou de déchets frais, il y a les meilleures solutions pour vous. En outre, vous pouvez également trouver une excellente solution pour granulation de bouse de vache compostée, fabrication de granulés de compost de fumier de poulet, production de granulés de compost à base de biocharbon, etc. à YUSHUNXIN. Venez les chercher maintenant!

solutions de compost récemment granulées