Can you offer the turnkey project solution for forest CDR in Canada?

Natürlich. As professional fertilizer equipment supplier, YUSHUNXIN can offer one-stop forest CDR (carbon dioxide removal) project solution with biochar pyrolysis + carbon based fertilizer granulation line. Including technology choosing, layout design, equipment manufacturing, delivery, installation, and staff training. Send us your information of materials, budget, area, required products, usw, YUSHUNXIN will offer you customized solutions to help you finish the premium biochar production and CDR forest Integration successfully.

How to make premium biochar from forest waste?

From the Canada customer email, he wanted to produce premium biohar with stable and homogeneous particle structure, reduced ash content and high fixed carbon percentage. Dafür, we especially design biochar pyrolysis system with wood crushing, impurity removing, controllable pyrolysis temperature, biochar cooling and gas waste treatment and recycle. This process are as follows:

For prepare biochar with high fixed carbon, the forest and wood waste are ideal materials, especially the sawdust.

To ensure the homogeneous particle structure, it is advisable to control the feeding materials size to 5-20 mm. Hier, the wood grinder can fully meet your requirements of both straw and log crushing.

Dann, to produce biochar with low ash content, you need to remove the impurities like small stones. Dafür, the rotary screener can help you a lot.

Darüber hinaus, it is also an important pre-treatment process for premium biochar making to dry the raw materials to lower than 10% moisture. This is helpful for not only high fixed carbon percentage biochar production, but also speed up the forest waste biomass pyrolysis process.

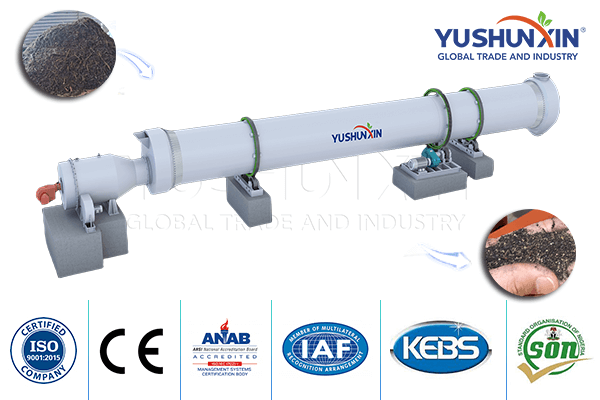

Then comes to the key process for biochar making from forest waste, the pyrolysis. There is continuous carbonization furnace with PLC controller and closed rotary drum design. Which help you easily control the biochar pyrolysis temperature (450–650°C), speed, time, and make materials heated evenly. This is beneficial for both get reduced ash content and high fixed carbon percentage.

In addition, after biochar pyrolysis, there is also water cooling system works for makeing biochar with stable particle structure. This unit cool down the finsihed biochar temperature slowly to prevents rapid oxidation or pulverization that could lead to structural fragility.

Can we blend with compost to produce biochar-based fertilizer pellets?

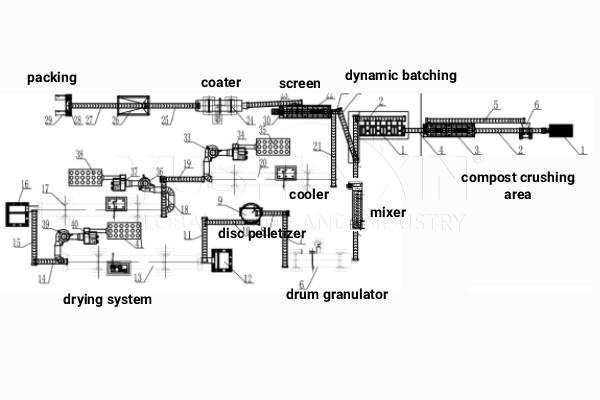

The Canada investor of solution for forest CDR also required a 20 TPH biochar based fertilizer granulation line with compost blend. Dafür, a rotary drum granulation line ist eine ideale Wahl. Not only large capacity, but also unique erosion resistant designs. Rubber lining and hit clean holes. Also, it can help you finish the industrial biochar fertilizer making for forest carbon sink better.

It mainly contains 2m*4m loader feeder, SXFLF-1000 vertical crusher, 2*8m powder screener, 4 cabins dynamic batching machine, double shaft mixer, SXZGZ-3210 rotary drum granulator, SXYZ-3600 disc pelletizer, SXHG-2424 rotary dryer *2 sets, SXHG-2424 rotary cooler, SXGS-2080 rotary sieving machine of granules, 2*8m coating equipment, .3*6m Cache storage bin and bagging scale*2 sets.

Can we add minerals and organic additives in the biochar fertilizer making line?

The answer is yes. This the reason why we design the dynamic batching machine with 4 hoppers (customized). After compost crushing and screening, you can precisely and simultaneously add powder biochar, mineral (like Ca, Mg, Si), organic additives by the dynamic batching equipment. Then blending evenly with the double shaft horizontal mixer.

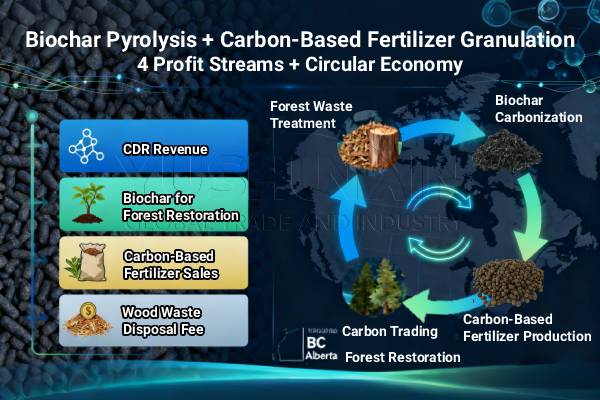

Is it profitable of the biochar pyrolysis + carbon based fertilizer granulation solution?

Natürlich. When you start a project of biochar pyrolysis + carbon based fertilizer granulation, you can get profits from 4 aspects at last.

Hier, this project can help you achieving a circular economy encompassing forest waste treatment → biochar carbonization → carbon-based fertilizer production → carbon trading → forest restoration.

What others can YUSHUNXIN do for your turnkey project solution for forest CDR in Canada?

As a turkey fertilizer equipment supplier, besides project design, YUSHUNXIN also can offer you:

The above are details about our communication with the customer about turnkey project solution for forest CDR in Canada. In addition, we also can offer you many other solutions related to fertilizer making. Einschließlich cow dung pellet making, chicken manure fertilizer granulation line, biogas digestate compost pellet production plan, usw. Welcome to contact us for them immediately!

Inhalt

- Can you offer the turnkey project solution for forest CDR in Canada?

- How to make premium biochar from forest waste?

- Can we blend with compost to produce biochar-based fertilizer pellets?

- Is it profitable of the biochar pyrolysis + carbon based fertilizer granulation solution?

- What others can YUSHUNXIN do for your turnkey project solution for forest CDR in Canada?

More Cases