What is the wet granulation method of compost pellets making?

Wet granulation involves the use of a liquid binder to help compost powder form granules.

3 Benefits of wet compost granulation

Commonly, granulating composted manure with wet granulation equipment provides several advantages for compost pellet making.

What is the process of wet compost fertilizer granulation method?

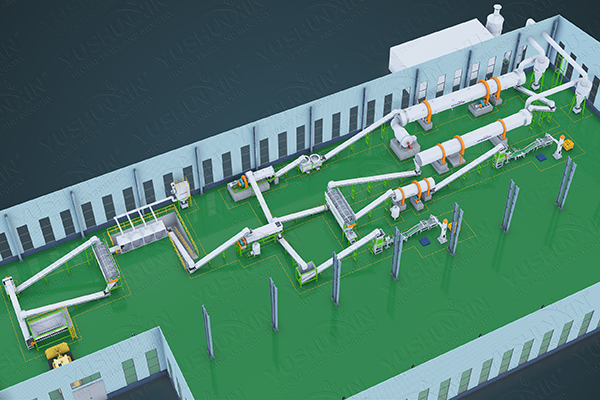

В целом, the process of a complete compost fertilizer pellet making is complex. Including batching machine → compost grinder → fertilizer mixer → wet granulation machine → compost screener → rotary dryer and cooler → coating machine → automatic packaging scale.

Вершина 3 types of wet granulation equipment

In this process, wet granulation equipment is indispensable. Considering the feedback from granular compost fertilizer manufactures, we designs 3 types of wet granulation machines for your choice.

What is the dry compost fertilizer granulation method?

As the name suggests, dry granulation of compost will produce compost granules in a dry condition. It mainly relies on mechanical extrusion force to press compost powder into fertilizer pellets.

What advantages of dry granulation favoured by fertilizer businesses?

How dry granulation line work to make compost in pellets?

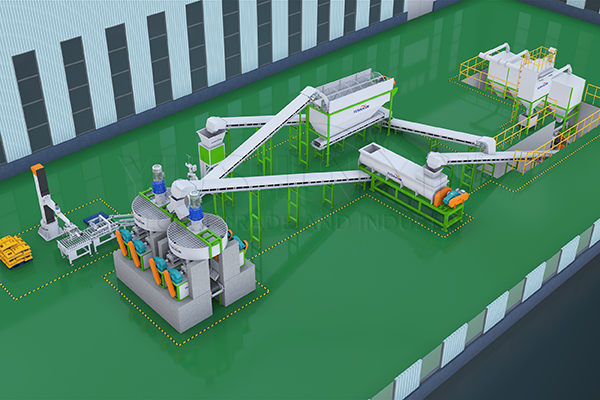

Как упоминалось выше, without dryer and cooler. Так, a dry granulation process of compost only contains material batching machine → compost crusher → fertilizer mixer → dry granulation machine → compost screener →automatic bagging equipment.

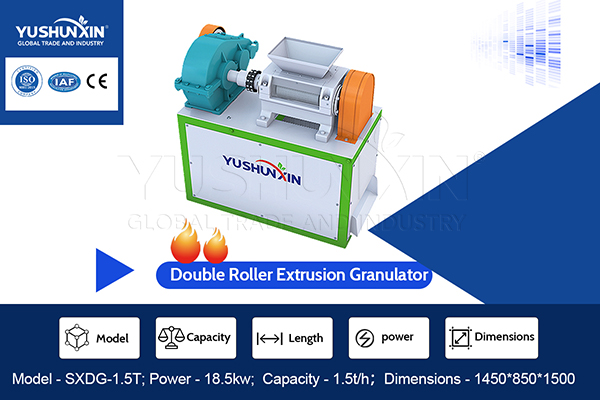

Common types of dry granulation machine of compost

В общем, for dry compost fertilizer granulation method, there are two types of equipment for your choice. Двухвалковый гранулятор can make 3-10 mm flat ball compost pellets for you. While flat die pellet mill will produce column granulated compost with 1-10 мм.

If you are interested in compost pellet making business,добро пожаловать, свяжитесь с нами сейчас. We will offer you the best solutions according to your conditions.

недавно гранулированные растворы компоста