Haut 2 des solutions pour mélanger du biochar avec du compost pour produire des granulés d'engrais

Communément, lorsque vous envisagez de produire un engrais granulaire au biocharbon avec un mélange de compost, il y a 2 technologies que vous pouvez choisir.

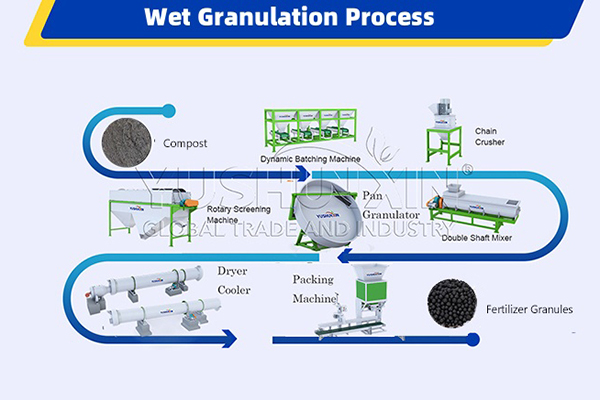

Ligne de granulation d'engrais au biocharbon humide (20%–40% d'humidité)

Si votre compost de biocharbon a une humidité de 20%-40%, acheter un ligne de granulation de compost humide est un choix idéal. Parce qu'il peut utiliser un liquide comme liant pour faciliter la formation d'engrais à base de biocharbon à partir du compost. En même temps, vous pouvez facilement contrôler la taille de l'engrais granulaire au biocharbon 1-8 mm par réglage de l'humidité.

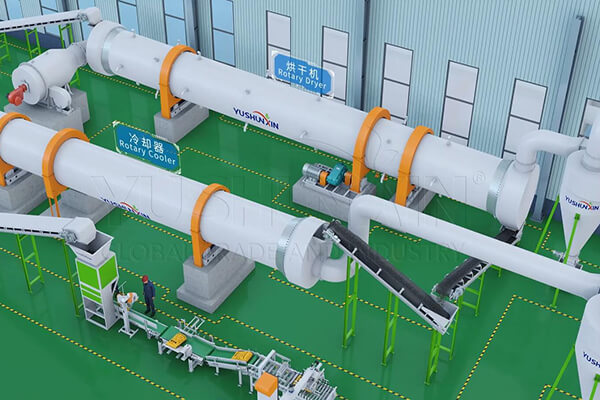

En général, un système complet de granulation humide de mélange de biochar et de compost se compose de 9 étapes. Traitement par lots, écrasement, mélange, granulation, dépistage, séchage, refroidissement, revêtement et emballage. Ce système convient aux investisseurs qui souhaitent produire des granulés d'engrais organiques au biocharbon avec un aspect boule ronde et une libération lente..

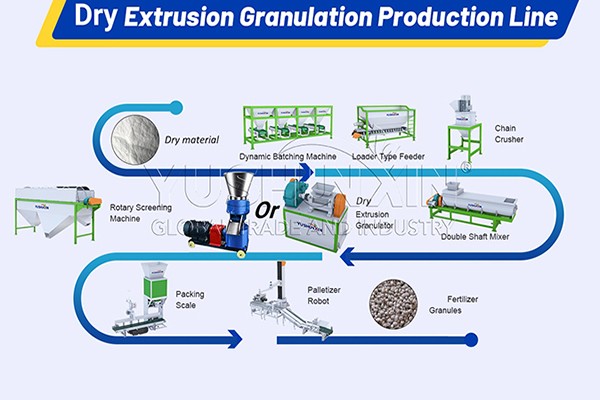

Granulation sèche d'engrais à base de charbon (sous 20% humidité)

Cependant, si vous envisagez de démarrer la production d'engrais à base de compost de biocharbon avec du matériel de compost dont l'humidité est inférieure à 20%, un système de granulation sèche est une meilleure option. Parce que, il peut convertir la poudre de compost de biochar en granulés d'engrais organiques sans impliquer d'eau. Par conséquent, vous pouvez réduire le coût d'achat d'un sèche-linge et d'un refroidisseur, qui est utilisé pour sécher l'engrais à base de carbone granulé à un niveau inférieur à 10% pour un stockage et un transport plus faciles.

Donc, pour la fabrication d'engrais à base de charbon avec technologie de granulation sèche, il vous suffit d'acheter 7 machines. Ce sont des machines à doser, broyeurs, mixer, équipement de granulation, tamiseuse, machine de revêtement et équipement d'ensachage. Cette solution est idéale pour les petites et moyennes entreprises qui recherchent une production d'engrais granulaires au biocharbon avec des coûts opérationnels inférieurs et un démarrage plus rapide..

Comment acheter le bon granulateur d'engrais à base de carbone pour votre projet?

Outre l'humidité du matériau, vous devez également considérer le type de granulés d'engrais à base de charbon requis? Forme ronde ou autres? Taille fixe ou réglable? dureté élevée ou non? Ici, YUSHUNXIN proposera diverses machines de granulation d'engrais pour répondre pleinement à vos besoins en matière de fabrication d'engrais biocharbon..

Granulateurs d'engrais au biochar de forme ronde

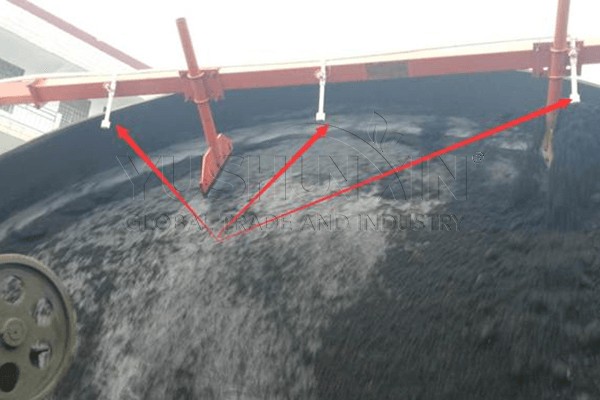

Lorsque vous avez besoin d'une granulation d'engrais avec du biochar et du compost mélangés, le granulateur à disque et le granulateur à tambour rotatif sont tous deux un excellent choix. Négativement, c'est une opération plus économique d'acheter un granulateur à double rouleau ou un broyeur à granulés à filière plate.

Fabrication de granulés d'engrais réglables à base de charbon de 1 à 8 mm

Envisager de produire des granulés d'engrais à base de carbone de différentes tailles avec le système à l'avenir, il est conseillé d'acheter un granulateur à pan ou un équipement de granulation à tambour. Vous pouvez réguler la production d’engrais de compost à base de biocharbon granulaire en 1-8 taille mm librement. Par le seul contrôle de l'humidité des matériaux, au lieu du remplacement des pièces.

Production de granulés d'engrais à base de carbone dur

Alors, si vous avez des exigences particulières concernant la dureté de l'engrais granulaire au biocharbon que vous produisez, vous pouvez choisir librement le nouveau type de granulateur d'engrais organique, pelletiseur à filière plate et extrusion à rouleaux. Sous l'action d'une pression mécanique, il y a une dureté élevée de 15-20 N dans votre engrais de charbon granulé.

| Équipement | Capacité (ème) | Taille des granules (mm) | Taux de granulation | Humidité alimentaire | Forme finale |

|---|---|---|---|---|---|

|

Granulateur à tambour rotatif |

1-30 | 3-6 | 90% | 20%-40% | ballon rond |

|

Pelletiseur à disque |

1-6 |

1-8 | 93% | 20%-40% | ballon rond |

| Granulateur à rouleaux | 1-4 | 3-10 | 95% | <20% | balle plate |

| Moulin à granulés plat | 1-2.5 | 3-10 | 95% | <20% | cylindrique |

| Granulés à dents agitées | 1-8 | 2-5 | 95% | 20%-40% | ballon rond |

Quelle est la citation de la ligne de production d'engrais à base de compost de biochar granulaire YUSHUNXIN?

La fourchette de prix d'une ligne de production d'engrais à base de compost de biocharbon granulaire s'étend généralement de $50,000 à $500,000. Cela dépend principalement de la configuration. YUSHUNXIN vous proposera votre solution personnalisée pour mélanger du biochar avec du compost pour la fabrication de granulés d'engrais.

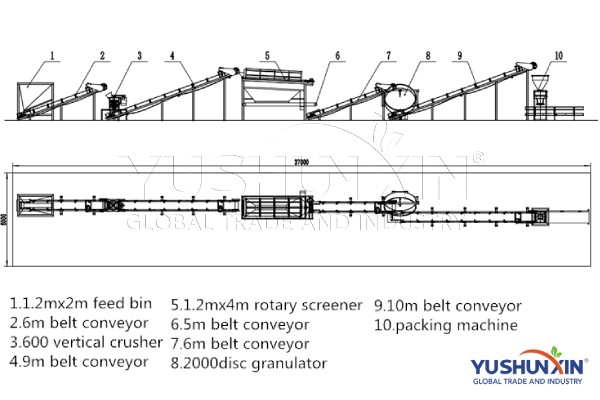

$60,000-$150,000 Solution de fabrication de granulés de compost de biocharbon

Une ligne de production de base pour fabriquer des granulés d'engrais carboné à partir de compost, dont le prix est généralement d'environ $60,000-$150,000. Il comprend généralement des machines essentielles pour la production d'engrais biocahr, telles qu'un broyeur., mixer, granulateur et équipement d'emballage. Ces configurations conviennent à 1-10 opérations de granulation de compost de biocharbon t/h qui nécessitent une approche pratique.

$150,000 et $300,000 fabrication d'engrais granulés à base de charbon

Comme la complexité de l'équipement de granulation d'engrais à base de carbone, ils coûtent entre $150,000 et $300,000. Ici, le système contient les machines de granulation de compost de biochar, du broyeur à l'échelle d'emballage. En même temps, il peut également répondre pleinement à vos exigences en matière de 1-10 production t/h d'engrais granulé à base de charbon.

$300,000-$500,000 coûts de production de granulés d'engrais biocharbon à partir de compost

Si vous préparez un $300,000-$500,000 budget, vous pouvez acheter un système de compostage de biochar aux granulés d'engrais entièrement automatisé. Il est spécialement conçu pour LA granulation d'engrais à base de carbone à grande échelle avec 10-20 Capacité TPH. Il s'agit également de l'ensemble des machines de granulation de compost, y compris la machine de palettisation.. Il n’y a presque pas besoin de main-d’œuvre et vous pouvez gagner plus d’argent.

Pouvez-vous proposer une usine de granulation d'engrais au biochar fini pour référence?

Absolument, en tant que fabricant professionnel d'équipements pour engrais et fournisseur de solutions, YUSHUNXIN a aidé les investisseurs de 100+ les pays démarrent avec succès leurs projets de granulation de compost de biochar. Le dernier en date se trouve en Malaisie. C'est un 20,000 Système de granulation de biochar et de compost MT Blend. Bienvenue à nous contacter dès maintenant pour votre propre solution de production d'engrais à base de carbone!

Existe-t-il des machines pour fabriquer du biocharbon et du compost pour la fabrication d'engrais à base de charbon?

Bien sûr. En tant que fabricant attentionné d'équipement de fabrication d'engrais de compost granulé, nous pouvons vous fournir une machine à biochar et un équipement de compostage de qualité.

D'autre part, avec machine de compostage d'engrais professionnelle, vous pouvez le terminer dans 20 jours. Pour ça, il y a un composteur dans le récipient pour une préparation rapide du compost, retourneur de compost à grande échelle, machine à composter économique à rainure, etc..

Pouvons-nous intégrer l'élimination du dioxyde de carbone (CDR) marché avec le système d'engrais biocharbon?

Pouvons-nous intégrer dans Élimination du dioxyde de carbone (CDR) marché avec le système d'engrais biocharbon?

Il est bénéfique non seulement pour la réduction des émissions de carbone liées à l’élimination des déchets de biomasse., mais aussi la séquestration du carbone et l'obtention de crédits carbone en produisant du biochar et des engrais à base de carbone.

En général, 1 tonne de biochar = 3 tonnes de déchets de biomasse éliminés = 2,0 à 2,4 tonnes de CO₂ éliminées. Et vous pouvez générer une source de revenus supplémentaire grâce à des crédits carbone d'une valeur de 200 à 400 € par tonne de CO₂..

Pouvez-vous proposer un récent projet de fabrication d'engrais au biochar pour le CDR à titre de référence? Bien sûr. Par exemple, le solution clé en main pour un projet CDR forestier au Canada, etc..

Outre la production d'engrais à base de compost de biocharbon granulaire, YUSHUNXIN peut également vous proposer de nombreuses autres solutions de fabrication de granulés de compost. Tel que plan de granulation d'engrais bio compost, ligne de granulation de compost de bouse de vache, projet de fabrication de granulés de fumier de poulet fermenté, etc.. Bienvenue à nous contacter pour le meilleur immédiatement.

solutions de compost récemment granulées