Is there a 20,000 tons annually blend biochar compost granulation solution?

The Malaysian fertilizer manufacturer required a 20,000 TPY biochar fertilizer granules making line. For this, they plan to mix biochar with compost as materials.

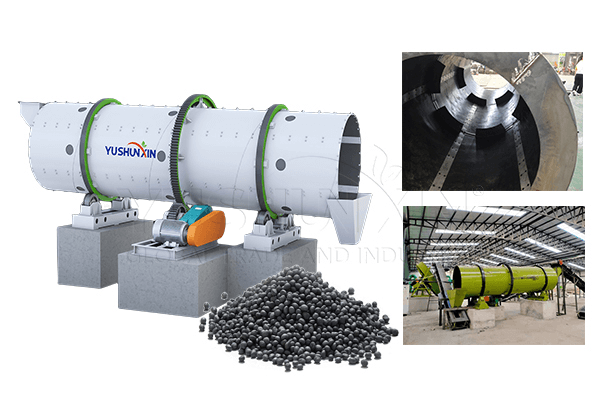

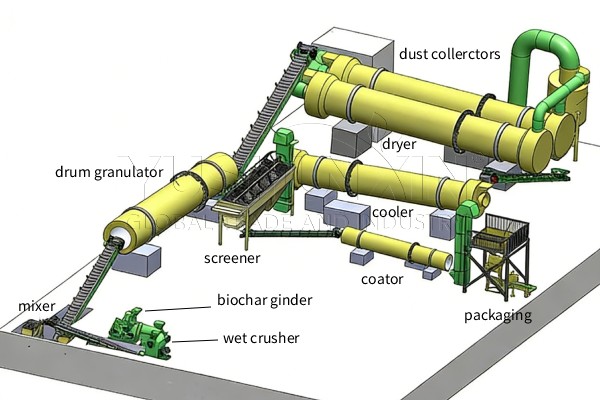

Because of over 20% moisture, the rotary drum granulation line is practical and profitable. For one thing, it makes use of mositure as binder to facilitate the blend biochar compost granulation process. For another, there are designs of rubber or stainless steel lining and sticking removing holes on the rotary drum granulator. This can greatly reduce the erosion to carbon-based fertilizer equipment.

In addition, the biochar compost granules making system adopts multiple steps to process biochar and compost. Including biochar crusher, compost grinder, double shaft blender, rotary drum granulation machine, pellets screener, rotary dryer and cooler, single bucket bagging equipment and conveyors. They can produce granular char-based fertilizer with 5-6 TPH output, round shape and adjustable size of 3-6 mm. Additionally, the biochar fertilizer granulation project costs only 126,860USD.

Can we mix biochar with compost with 30%–40% moisture to make char-based fertilizer granules?

For the compost material mixed with biochar, there is compost with 30%–40% moisture collected by Malaysia customer. They wanted to know clearly that does it need drying of compost before start the blend biochar compost granulation system?

As the above biochar fertilizer granule making line showed, it is not necessary to dry compost when your plan to mix biochar with 30%–40% moisture compost to prepare fertilizer pellets. For make biochar fertilizer with composted manure with 30%–40% water content, mixing with dry biochar powder will reduce the moisture to around 25%–35%. This is ideal for char-based fertilizer making with rotary drum granulation system. What’s more, to help you produce commerical carbon cased fertilizer pellets better, we also design a hot air drying system to further reduces moisture below 10%. Which will ensuring the granulated char based fertilizer meets interinational commercial standards.

Can we maximize carbon credits with this biochar fertilizer granulation system?

The biochar pyrolysis plant customer from Malaysia told us that the final purpose is to maximize carbon credits while make profits from char-based fertilizer selling. Is it possible?

Of course. Compared with turn biomass into biochar by pyrolysis only, biochar fertilizer granule making further maximize carbon credits by organic waste disposal, reduce chemical fertilizer using and soil improvement indirectly. You can choose to wholesale the carbon credit to the agriculture industries or industrial factory.

The above are details about our communication with the customer about blend biochar compost granulation solution for Malaysia. In addition, there are also turnkey solution for carbon dioxide removal, which from biochar pyrolysis to char-based fertilizer granules making, manure waste composting, 20TPH compost pelleting plans, etc. Welcome to contact us for your own solutions immediately!

More Cases