Why drum granulation line is the best for $500,000 cost organic fertilizer granulation plant?

When planning to set up an organic fertilizer granulation plant with a budget of around $500,000, one of the most efficient and reliable choices is a drum granulation line. This technology has been proven in the fertilizer industry for decades, and it is especially suitable for industrial compost granulation plant investors aiming to balance cost and performance. There are 3 key reasons why the drum granulation line is the best choice: its large capacity, unique erosion-resistant designs, and high automation.

Maximum 30 TPH organic fertilizer granule making

For industrial compost pellet fertilizer making, a large scale output is necessary. Here, YUSHUNXIN rotary drum granulation line can fully meet your requirements of 15-20 t/h granular organic fertilizer making. Namely, the annual output of your compost granulation plant can reach 150,000-180,000 tons. the large scale compost granulation makes drum granulators stand out. For a $500,000 investment plant, there is a better long-term returns.

Unique erosion resistance design for large scale compost granulation

Moreover, compared organic fertilizer granulation line, only the rotary drum granulator designed with extra erosion resistance for wet compost processing. Including rubber lining and stick cleaning holes. feature unique erosion-resistant designs.

High automation – 1-2 workers only

Additionally, its high automation enhances efficiency and reduces labor costs. Modern drum granulation lines are equipped with PLC control system. This means you can control the whole industrial organic fertilizer pellet making line, from compost batching to packaging, without worker operation. You only need to employ 1-2 workers for materials feeding.

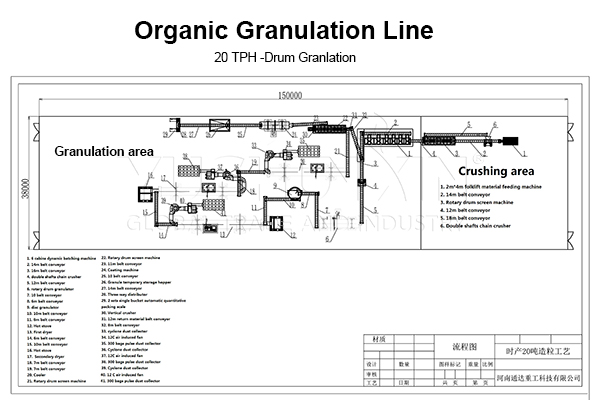

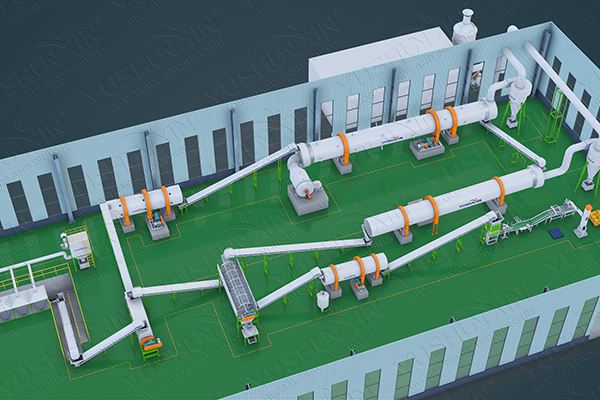

What is the layout of the industrial organic fertilizer granulation line?

With $500,000 investment, for a complete organic compost pellet making system purchasing, its capacity is about 15-30 TPH. Therefore, the most recommend configuration is folklift feeder, SXLTF-800|| double shaft chain crusher, rotary powder screener, dynamic batching machine, SXLTF-800|| double shaft chain crusher, SXZGZ-3210 rotary drum granulator, SXYZ-3600 disc pelletizer, SXHG-2424 rotary dryer, SXHG-2424 cooler, SXGS-2040 granules rotary sieving machines, coating machine, double bucket packing scale, SXFLF-600 vertical return material grinder, dust collectors, belt conveyor and other accessories. So, it finish the commercial granular organic fertilizer making with characteristics of

In general, for the workshop of rotary drum granulation line of compost materials, you need to prepare an area of 5,000-6,000㎡.

Can you offer detailed parameters of the $500,000 organic fertilizer pellet making system?

Of course. For the above organic fertilizer granulation line with a budget of $500,000, below is the detailed configuration with approximate pricing.

| Equipment | Model | Capacity (T/H) | Function | Qty | Price (USD) |

|---|---|---|---|---|---|

| Folklift Feeder | 15-20 | Compost feeding | 1 | $8,000 – $12,000 | |

| Double Shaft Chain Crusher | SXLTF-800|| | 10-15 | Crushing compost lumps | 2 | $7,000 – $10,000 |

| Rotary Powder Screener | SXGS-2040 | 10-20 | Remove impurities | 1 | $6,000 – $9,000 |

| Dynamic Batching Machine | 15-20 | Precise proportioning | 1 | $15,000 – $20,000 | |

| Rotary Drum Granulator | SXZGZ-3210 | 15-30 | Spherical granulation | 1 | $55,000 – $80,000 |

| Disc Pelletizer | SXYZ-3600 | 4-6 | dual granulation | 1 | $12,000 – $18,000 |

| Rotary Dryer | SXHG-2424 | 15-20 | Reduce moisture | 2 | $25,000 – $30,000 |

| Rotary Cooler | SXHG-2424 | 15-20 | Cool & harden granules | 1 | $20,000 – $25,000 |

| Rotary pellets Screener | SXGS-2040 | 10-20 | Granule classification | 1 | $10,000 – $15,000 |

| Coating Machine | 15-20 | Anti-caking treatment | 1 | $8,000 – $12,000 | |

| Double Bucket Packing Scale | 20-50kg/bag | packing&sealing | 1 | $10,000 – $15,000 | |

| Vertical Grinder | SXFLF-600 | 3-5 | crush oversized pellet | 1 | $6,000 – $8,000 |

| Dust Collectors | gas/dust disposal | 3-5 | $15,000 – $20,000 | ||

| Belt Conveyors | Material transfer | 8-10 | $2,000-$3,000 | ||

| Accessories | Cables, control panels, etc | $4,000-$6,000 |

This quote is for reference only, the precise cost will varies according to the equipment design details, material, extra requirements, etc. Welcome to contact us for the precise quote for your organic compost granulation system now!

Is it suitable for 100,000 tons annual organic fertilizer pellet making project?

Of course. For investors targeting extremely large-scale compost pellet production, such as 1,00,000 tons per year, the $500,000 drum granulation line is enough.

As mentioned above, it can produce 15–20 tons of granular organic fertilizer per hour. When you make it work 2 shifts a day and 10 hours per shift, you can prepare 80,000-120,000 tons of organic fertilizer pellets a year. In addition, if you plan to enlarge your organic fertilizer pellets making business scale, YUSHUNXIN also can offer you parallel lines, which can operate on the basis of the system.

How long does the $500,000 cost organic fertilizer granulation plant profitable?

Profitability is one of the most critical concerns for fertilizer investors. For the $500,000 organic fertilizer granulation line, return on investment (ROI) is typically achieved within 1–2 years under standard market conditions. This calculation considers equipment depreciation, operational expenses, labor, and raw material costs, balanced against revenue from selling granular organic fertilizers.

In summary, with proper raw material supply and steady sales channels, a $500,000 organic fertilizer granulation plant becomes profitable in just a few seasons. After the first 2 years, it can generate significant net income annually, making it a highly sustainable long-term investment.

If you prefer stirring teeth granulation solution for hard pellets making or roller press granulation plan for granulating dry compost, there are customized project design for you. Moreover, YUSHUNXIN also offer $300,000 compost granulation plan, $100,000 organic fertilizer pellet making solution, etc. Come to get them now!

recently granulated compost solutions