Top 2 solutions to mix biochar with compost to produce fertilizer granules

Commonly, when you plan to produce granular biochar fertilizer with compost blend, there are 2 technologies you can choose.

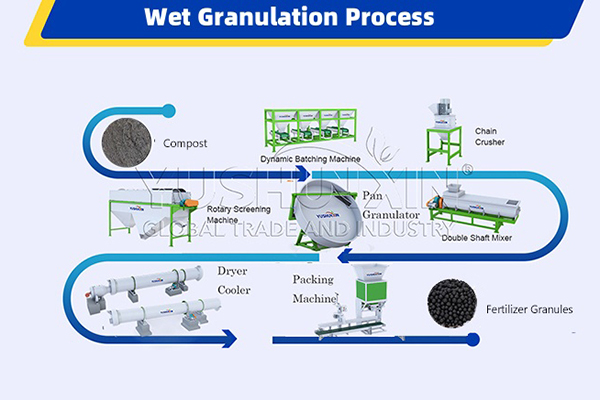

Wet biochar fertilizer granulation line (20%–40% moisture)

If your biochar compost material has a moisture of 20%-40%, buy a wet compost granulation line is an ideal choice. Because it can use liquid as binder to facilitate the biochar based fertilizer formation from compost. At the same time, you can easily control the granular biochar fertilizer size in 1-8 mm by moisture adjustment.

In general, a complete wet granulation system of biochar and compost blending consist of 9 stages. Batching, crushing, mixing, granulation, screening, drying, cooling, coating and packing. This system suits investors who want produce biochar organic fertilizer granules with a round ball appearance and slow release.

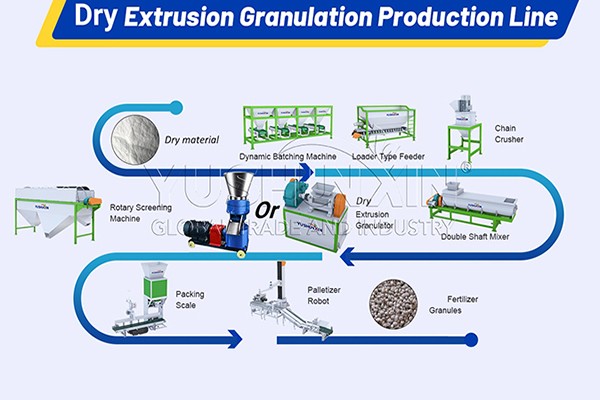

Dry granulation of char‐based fertilizer (under 20% moisture)

However, if you plan to start biochar compost based fertilizer production with compost material with moisture less than 20%, a dry granulation system is a better option. Because, it can convert biochar compost powder into organic fertilizer granules without water involving. Accordingly, you can reduce the cost on dryer and cooler purchasing, which is used to dry granulated carbon based fertilizer to lower than 10% for easier to store and transport.

Therefore, for char-based fertilizer making with dry granulation technology, you only need to purchase 7 machines. They are batching machine, grinders, blender, pelleting equipment, sieving machine, coating machine and bagging equipment. This solution is ideal for small to medium enterprises seeking granular biochar fertilizer production with lower operational costs and faster startup.

How to buy the right carbon based fertilizer granulator for your project?

Besides material moisture, you also need to consider that what kind of char-based fertilizer pellets required? Round shape or others? Fixed or adjustable size? high hardness or not? Here, YUSHUNXIN will offer various fertilizer granulation machines to fully meet your requirements for bio char fertilizer making.

Adjustible 1-8mm char-based fertilizer pellet making

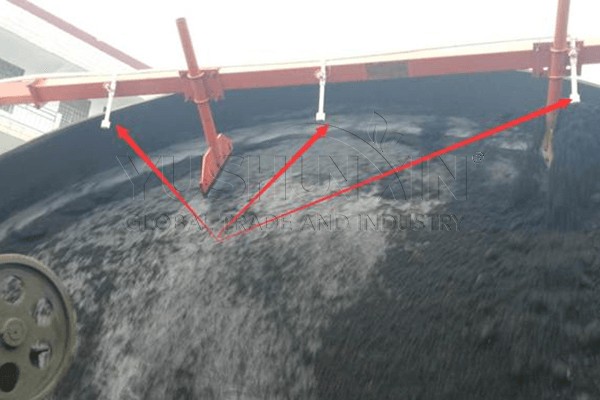

Considering produce carbon-based fertilizer pellets into various sizes with the system in the future, it is advisable to buy a pan granulator or drum granulation equipment. You can regulate the granular biochar based compost fertilizer production into 1-8 mm size freely. By only material moisture control, instead of parts replacement.

Hard carbon-based fertilizer granules production

Then, if you have special requirement on the hardness of granular biochar fertilizer you produce, you can freely choose the new type organic fertilizer granulator, flat die pelletizer and roller extrusion. Under the action of mechanical pressure, there is a high hardness of 15-20 N in your granulated char fertilizer.

| Equipment | Capacity (t/h) | Granule Size (mm) | Granulation Rate | Feed Moisture | Final shape |

|---|---|---|---|---|---|

|

Rotary Drum Granulator |

1-30 | 3-6 | 90% | 20%-40% | round ball |

|

Disc pelletizer |

1-6 |

1-8 | 93% | 20%-40% | round ball |

| Roller granulator | 1-4 | 3-10 | 95% | <20% | flat ball |

| Flat pellet mill | 1-2.5 | 3-10 | 95% | <20% | cylindrical |

| Stirring teeth pelletizer | 1-8 | 2-5 | 95% | 20%-40% | round ball |

What is the quotation of YUSHUNXIN granular biochar compost based fertilizer production line?

The price range for a granular biochar compost-based fertilizer production line typically spans from $50,000 to $500,000. This is mostly depened on the configuration. YUSHUNXIN will offer your customized solution to mix biochar with compost for fertilizer pellet making.

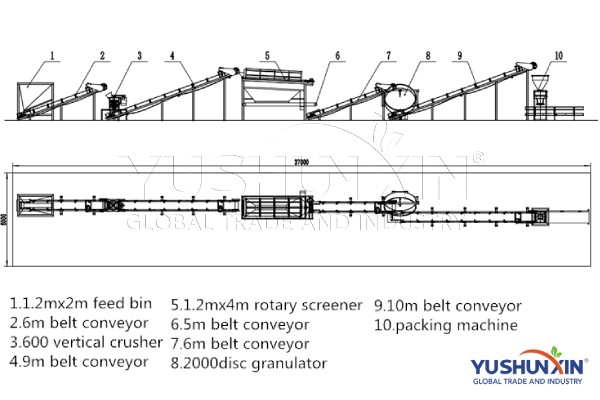

$60,000-$150,000 biochar compost granules making solution

A basic production line for making carbon fertilizer pellet from compost usually pricing around $60,000-$150,000. It usually includes essential biocahr fertilizer machinery such as a crusher, mixer, granulator and packaging equipment. These setups are suitable for 1-10 t/h biochar compost granulation operations that require some hands-on approach.

$150,000 and $300,000 granulated char-based fertilizer making

As the complexity of the carbon-based fertilizer pelleting equipment, they costs between $150,000 and $300,000. Here, the system contains the biochar compost granulating machines from crusher to packaging scale. At the same time, it also can fully meet your requirements for 1-10 t/h output of granulated char-based fertilizer.

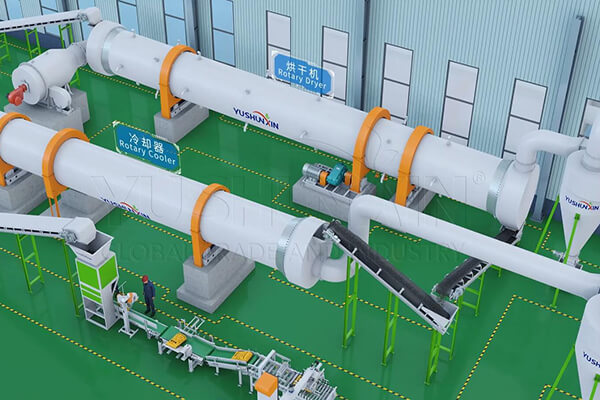

$300,000-$500,000 costs to produce biochar fertilizer pellets from compost

If you preparing a $300,000-$500,000 budget, you can buy a biochar compost to fertilizer granules system with fully automation. It is especially designed for THE large scale carbon based fertilizer granulation with 10-20 TPH capacity. This is also consists the whole sets compost granulation machines including palletizer machine. There is nearly no labor force needed and you can make more money.

Can you offer finished biochar fertilizer granulation plant for reference?

Absolutely, as a professional fertilizer equipment manufacturer and solution provider, YUSHUNXIN had help investors from 100+ countries start their biochar compost granulation projects successfully. The latest one is located in Malaysia. It is a 20,000 MT blend biochar and compost granulation system. Welcome to contact us for your own carbon-based fertilizer production solution now!

Is there machines for making biochar and compost for char-based fertilizer manufacturing?

Of course. As a considerate manufacturer for granulated compost fertilizer making equipment, we can provide you with quality biochar machine and composting equipment.

On the other hand, with professional fertilizer composting machine, you can finish it within 20 days. For this, there are in-vessel compostor for fast compost preparing, large scale wheel type compost turner, economical groove type compost machine, etc.

Can we integrate into Carbon Dioxide Removal (CDR) market with the biochar fertilizer system?

Can we integrate into Carbon Dioxide Removal (CDR) market with the biochar fertilizer system?

It is beneficial for not only the carbon reduction of biomass waste disposal, but also the carbon sequestration and carbon credit earning by produce biochar and carbon-based fertilizer.

In general, 1 ton of biochar = 3 tons of biomass waste disposal = 2.0–2.4 tons of CO₂ removed. And you can generates an additional revenue stream through carbon credits valued a€200–€400 per ton of CO₂.

Can you offer recent biochar fertilizer making project for CDR for refrence? Of course. For example, the turnkey solution for forest CDR project in Canada, etc.

Besides granular biochar compost based fertilizer production, YUSHUNXIN also can offer you many other compost pellet making solutions. Such as bio compost fertilizer granulation plan, cow dung compost pelleting line, fermented chicken manure pellet manufacturing project, etc. Welcome to contact us for the best one immediately.

recently granulated compost solutions