Biochar pyrolysis line: Convert biomass waste into carbon sink

The biochar pyrolysis process is a central technology in carbon reduction project. By pyrolysis, which is in an absence of oxygen condition, you can process organic biomass into biochar. In this process of biochar production, you not only realize the carbon reduction of biomass waste disposal, but also get biochar, which can improves carbon dioxide absorption by soil improvement. So, you can start your carbon sink project.

For large scale of biomass pyrolysis, there is industrial biochar production line for you. It contains machines of biomass grinding, biochar pyrolysis, biochar cooling and dust collection. With this system, you can prepare quality biochar with stable and homogeneous particle structure, reduced ash content, high fixed carbon percentage, and compliance with standards required for CDR certification.

Granular biochar production: Easy to apply with agricultural equipment

Although biochar from simple pyrolysis performs well as a soil amendment, many fertilizer manufacturers choose further process biochar pellets to enhance value and simplify logistics. These granulated biochar has features of strong, uniform, easy to apply with agricultural spread equipment and long-lasting carbon storage.

Are there solutions for commercial biochar granules making?

Конечно. When you plan to turn pyrolysis biochar into pellets, тот линия грануляции с двумя валками is an ideal choice. Without drying and cooling and fully meet you requirements for 3-10 mm biochar granules production. В общем, it contains material feeder, biochar crusher, roller extrusion granulator, rotary screening equipment and bagging machine.

Carbon-based fertilizer making: Mixing biochar with compost and minerals

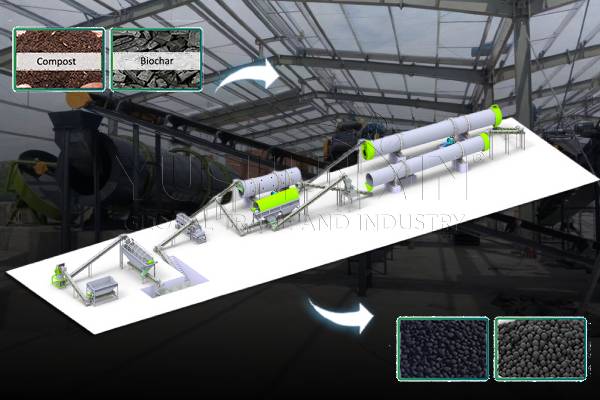

Кроме того, the most recommended one of carbon reduction technologies is carbon-based fertilizer making. This process mixes biochar with compost and minerals such as Ca, Mg, and Si, to make fertilizer pellets. Because biochar acts as a high-capacity carbon sink while also improving microbial life, the produced carbon based fertilizer performs significantly better of supporting crops and plants growth. Поэтому, you can earn more carbon sink.

How to mix biochar with compost to make carbon-based fertilizer?

В общем, it contains 8 steps of a complete biochar fertilizer granulation line from compost. Including material batching machine, дробилка компоста, double shaft mixer, fertilizer granulator, sieving machine, сушилка и охладитель (optional), coating machine and packaging scale. They can make granular biochar fertilizer of round ball shape, 1-10 mm size, customized nutrients, и т. д..

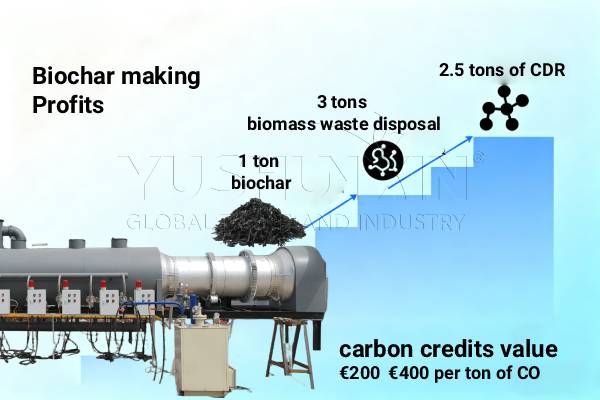

It is profitable for starting Carbon Dioxide Removal by biochar making and fertilizer granulation?

It is profitable for starting Carbon Dioxide Removal by biochar making and fertilizer granulation?

В общем, 1 ton of biochar = 3 tons of biomass waste disposal = 2.0–2.4 tons of CO₂ removed. And you can generates an additional revenue stream through carbon credits valued a€200–€400 per ton of CO₂.

Так, whether as a local government, a business, or an individual, the above 3 carbon reduction technologies can help you earn profits.

Is there operational carbon dioxide removal project for refernece?

Ответ: да. With customized turkey solutions for CDR project and quality equipment of biochar making and fertilizer making, many investors choose the YUSHUNXIN. Such as the customer of forest carbon sink project in Canada. He buy a system of biochar pyrolysis and carbon-based fertilizer granulation. And now, it works well.

The solutions of biochar pyrolysis lines, granulated biochar production, and carbon-based fertilizers represents good invest opportunity. Not only do they provide effective biomass waste disposal and carbon sequestration, but they also offer new revenue opportunities through carbon credits. If you have any other requirements about the projects, welcome to contact ЮШУНЬСИНЬ now!

Содержание

- Biochar pyrolysis line: Convert biomass waste into carbon sink

- Granular biochar production: Easy to apply with agricultural equipment

- Carbon-based fertilizer making: Mixing biochar with compost and minerals

- It is profitable for starting Carbon Dioxide Removal by biochar making and fertilizer granulation?

- Is there operational carbon dioxide removal project for refernece?

недавно гранулированные растворы компоста