Как переработать частицы несоответствующего размера для переработки в процессе грануляции компоста?

В общем, Скорость изготовления компостных гранул необходимого размера может достигать 90%-95% с YUSHUNXIN грануляторы компоста. Это может обеспечить минимальные потери материала.. Все еще, по-настоящему гранулировать компост без отходов, остальные 5%-10% гранулированных компостных удобрений — слишком больших или слишком маленьких — необходимо правильно переработать.. Commonly, для этого нужно только 2 steps.

Отделите гранулы компоста необходимого размера от неквалифицированных.

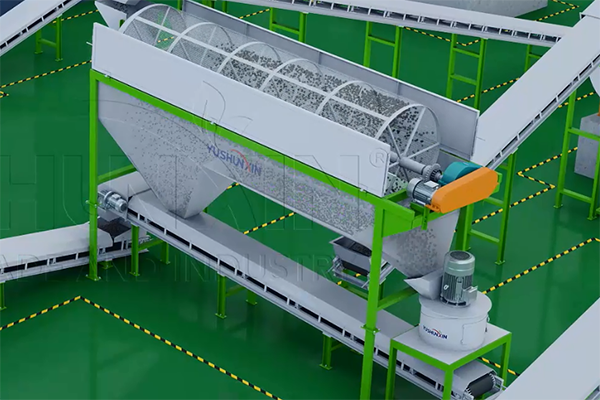

Первый, вам необходимо отделить гранулированные гранулы компостных удобрений от тех, которые не соответствуют вашим требованиям. Для этого, сортировочная машина с вращающимся барабаном могу закончить это идеально. С вращением ситовой сетки, он может разделить гранулированное компостное удобрение на необходимый размер., слишком большой и слишком маленький. There are 1-20 Модели сепараторов компоста производительностью т/ч для вас.

Дробление возвращенных частиц удобрений в мелкий порошок

Следующий, Вы можете измельчить неквалифицированные гранулы компоста в мелкий порошок для возврата в машину для изготовления компостных гранул.. Для возвращаемых компостных гранул дробление цепная дробилка это лучший выбор. Из-за небольшого необходимого пространства, вы можете закрыть его непосредственно перед роторным ситом. А именно, не нужен дополнительный ленточный конвейер.

Эта система может значительно сократить отходы материала на заводе по гранулированию компоста.. Если вам нужна неквалифицированная система переработки компостных гранул, добро пожаловать, свяжитесь с нами сейчас!

Существует ли система переработки порошкообразного пылевидного материала для безграничного гранулирования компоста??

Кроме возврата гранулированных компостных удобрений, вы также можете достичь нулевых отходов, предотвращая образование пыли. Для этого, YUHSUNXIN может предложить вам лучшие решения., который содержит:

Профессиональные пылесборники

Первый, Наиболее эффективным решением для переработки разбросанного порошка при гранулировании компоста является использование профессиональных пылесборников.. Включая циклонные пылесборники, пылесборники водяной завесы, и комнаты падения пыли. Эти устройства улавливают частицы, находящиеся в воздухе, во время изготовления компостных гранул., особенно на этапах сушка и охлаждение компоста. Компостный материал в системе пылеулавливания можно переработать для повторного приготовления гранулированного компостного удобрения..

Машина для внесения удобрений с пылезащитными крышками

Кроме того, для дальнейшего сокращения отходов при гранулировании компоста, вы также можете установить пылезащитные чехлы на машину, чтобы компостный порошок было легче разбрасывать.. Такие как ленточная транспортировка и сортировка. Здесь, YUSHUNXIN может предложить вам эту специальную машину для безотходного гранулирования компоста..

In summary, вполне возможно гранулировать компост без отходов. ЮШУНЬСИНЬ можем предложить вам лучшие решения. Добро пожаловать, свяжитесь с нами для получения собственного плана производства гранулированных компостных удобрений немедленно..

недавно гранулированные растворы компоста