3 types of round ball compost pellet machine in YUSHUNXIN

In the realm of compost management, YUSHUNXIN offers a variety of machines and solutions for converting composted material into organic fertilizer granules. But for making round pellets, there are 3 types of round ball compost pellet machine widely used in. They can fully cater your needs of 1-30 TPH output, economical price and hard compost pellet manufacturing.

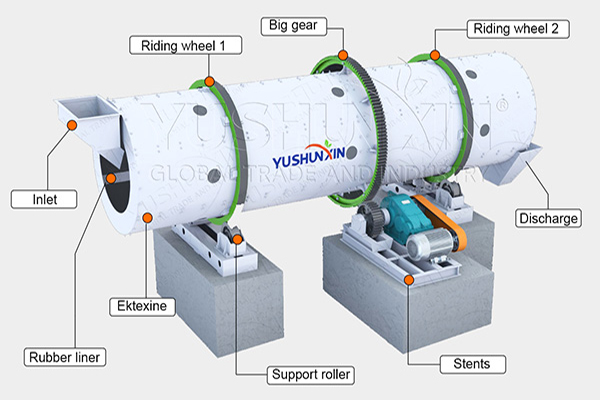

Rotary drum pelletizer for large compost fertilizer granulation plant

If you plan to setup a large compost fertilizer granulation plant, it is advisable to buy rotary drum pelletizers.

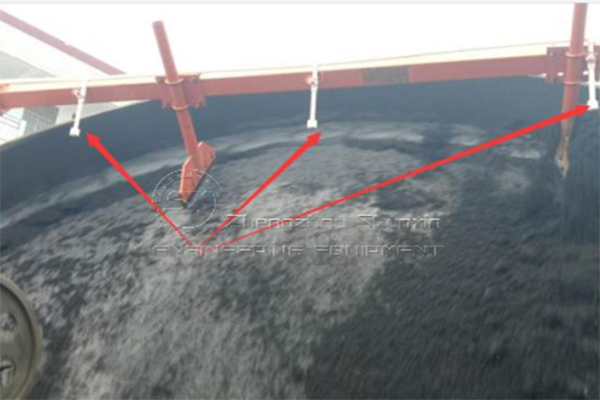

Under the action of liquid cohesion and natural force from drum rotation, the compost powder will roll and form into spherical organic fertilizer granules.

In addition, because of drum design, it can easily process 1-30 tons of granular organic fertilizer for you per hour. At the same time, for large scale industrial organic fertilizer pellet making from compost, the machine is designed with unique corrosion resistant system. Including rubber lining and cleaning holes.

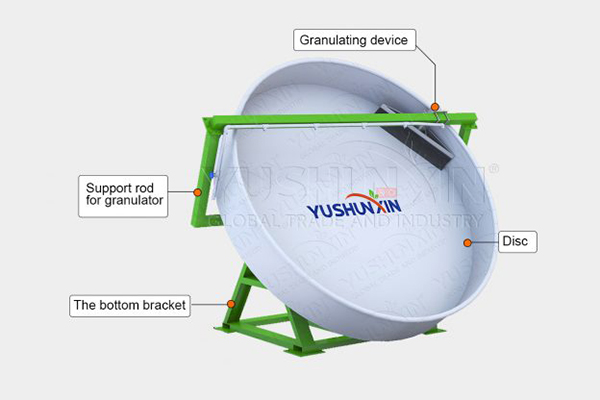

Economical disc granulation equipment of compost

At the same time, there is also disc pan granulator for economically produce organic fertilizer pellets in round shape in a small scale.

For one thing, similar with the drum granulation equipment, the pan pelletizer granulate composted fertilizer by liquid cohesion and disc rotation. So, you can make round-shaped fertilizer pellets quickly. Also, you can control granulated compost size of 1-8 mm by moisture and disc angle adjustment.

For another, with 1-6 t/h output, the pan pellet machine of compost has a favourable price. It is only $3,500-$15,000. Therefore, you can finish the small scale organic fertilizer granules making at a lower cost.

New type organic fertilizer granulator for hard granulated compost making

However, if you want produce round ball compost pellet with higher hardness, you can use our new type organic fertilizer granulator.

| Equipment | Capacity (t/h) | Granule Size (mm) | Granulation Rate | Feeding Moisture |

|---|---|---|---|---|

|

Rotary Drum Granulator |

1-30 | 3-6 | 90% | 20%-40% |

|

Disc Granulator |

1-6 |

1-8 | 93% | 20%-40% |

|

New Type Organic Fertilizer Granulator |

1-8 |

2-5 |

97% |

20%-40% |

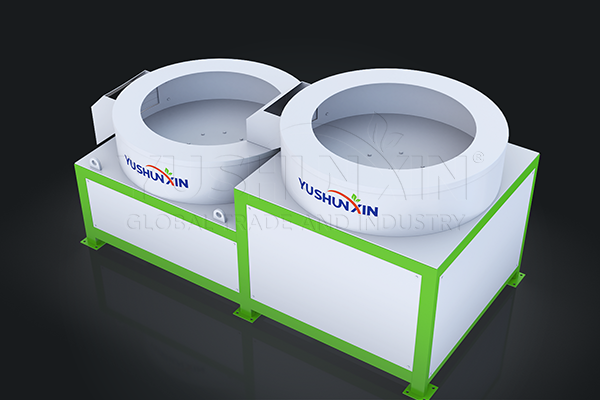

Is there equipment for processing finished compost pellets into more rounded?

Commonly, some compost granules fertilizer manufacturers has a double roller granulation line or flat die granulator. How to make the finished organic compost pellets more rounded?

For this, our engineers design fertilizer polishing machine. Which is to smooth and round the compost fertilizer granules, giving them a uniform and aesthetic spherical shape. It operates by placing the rough, irregularly shaped compost granules into the machine. Then, because of circular pan rotating, the granulated compost will tumble against each other and against the walls of the pan. Friction and pressure created during this process gradually shave off the rough edges and corners of the organic compost granules. In addition, according to your needs, we can provide you with polishing machine with one, two or three stages.

Do we need to add fertilizer polishing machine after the above round ball fertilizer pelletizers?

Absolutely not. Especially in the process of spherical organic fertilizer making with disc pellet equipment and drum granulator. On the one hand, the granular compost pellets is formed by natural rotation of the equipment. So, it is easier to broken down under the action of the high speed rotation. On the other hand, the granulated compost from the above the round ball compost pellet machines can fully meet your requirements. Commonly, many organic fertilizer manufacturers add the granule polisher in dry fertilizer granulation system. Including double roller granulation line and flat die pelletizing project.

Is it profitable to start a round compost pellet production line?

As mentioned above, the round ball compost granule is more popular with farmers because of better fertilizer spreader suitability and nutrient release. The price is at least $60-$300 per ton. Then, a complete 1-20 t/h spherical compost pellet making system costs $60,000-$450,000. Which contains batching machine, crusher, mixer, granulator, dryer, cooler, coating machine and packaging scale. In general, you can get back the investment in round ball compost granule plant setup with half to two years.

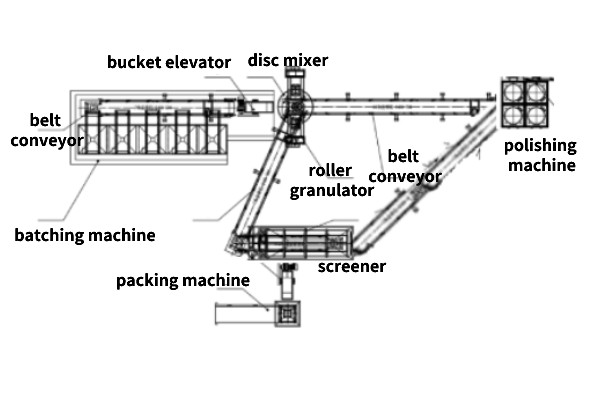

What is the design of round ball fertilizer making line with roller granulator?

If you want to produce round shape compost pellets at a lower cost, the system of double roller granulation machine + polishing machine is recommended. Without drying and cooling system, a 20 TPH round ball fertilizer granulation line pricing about $300,000. In general, it contains equipment of batching machine, mixer, roller extrusion granulators, fertilizer polishing machine, rotary screener and pellet bagging scale.

3 Items you must focus on in the round ball compost pellet fertilizer making process

When you make compost into round ball organic fertilizer pellets, besides granulator, you also need to pay attention to the following 3 aspects.

In addition, you need to focus on the moisture of compost material in the whole round ball organic fertilizer pellet making process. Compost fertilizer particle formation requires appropriate moisture (20%-40%), too much or too little will affect the formation. For this, YUSHUUNXIN can offer you disc and drum granulator with special water spray devices according to your needs.

What benefit of make compost into organic fertilizer pellet with round ball shape?

From the feedback of our past customers, there is a larger amount of compost organic fertilizer manufacturers prefer making it granulated compost into round ball shape. Because round ball compost fertilizer production has benefits as follows:

Besides, round ball compost pellet machine, YUSHUNXIN also can offer you other compost fertilizer granulation equipment. Such as double roller press granulator for plat ball granulated compost making and flat die pelletizer, which preparing column compost granule. Even industrial composting equipment. Moreover, if you need a complete granulated compost making line, we can offer you the best solutions according to your actual conditions.

recently granulated compost solutions