What can rotary coating machine do for better compost pellet production?

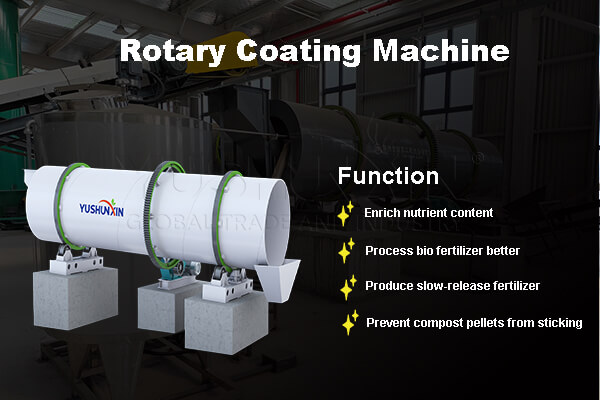

A rotary coating machine plays a crucial role in effectiveness compost pellet production. With the fertilizer drum coater, you can prepare granular compost fertilizer with rich nutrients, slow release, high microorganisms survival and no sticking.

What is the fertilizer drum coating machine working process?

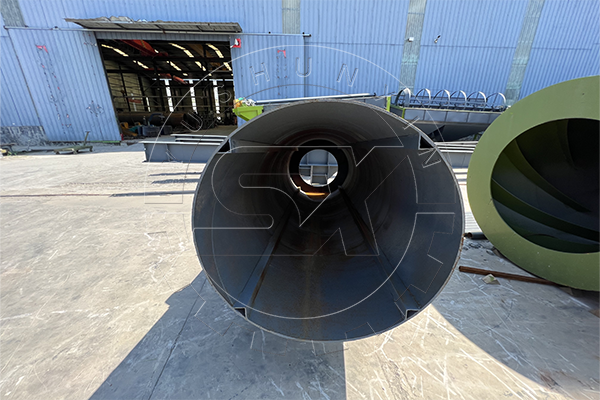

Essentially, the coating of organic compost granules processes on a straightforward yet effective. It mainly relies on the drum rotation and spray system to work for better granular compost fertilizer making. Usually, this can be divided into 3 steps:

The key to the effectiveness of the drum coating machine lies in its ability to maintain precise control over the granular compost fertilizer coating process. Parameters such as drum speed, spray rate, and drying conditions are meticulously managed to achieve the production of desired compost pellet fertilizer. Here, the YUSHUNXIN fertilizer coater can fully meet your requirements.

Top 4 types of compost granules coating machine in YUSHUNXIN?

YUSHUNXIN, a leading manufacturer of agricultural machinery, offers a variety of drum coating machines designed to meet diverse needs. Including 1-30 TPH capacity, both powder and liquid coating for compost fertilizer pellet making.

Large scale fertilizer rotary coating equipment

If you plan to buy a fertilizer coater for making organic fertilizer pellet from compost, there are 7-30 t/h models for your choice. For example, for 20 TPH coated compost pellets making, the15-30 TPH capacity is suitable for you. With 1800 mm internal diameters and 8000 mm length, the power of fertilizer coater is only 15 kw.

Small scale fertilizer coaters

Designed for for small scale compost granule coating, there are 1-5 TPH and 5-7 TPH models for your choice. The drum coating machines have a internal diameter of 1200-1400 mm and length of 400 mm. Their power is 5.5-7.5 kw, which means a low energy consumption for compost pellet processing.

Liquid coater for compost granules making

At the same time, you also can use the fertilizer rotary coater to add liquid coat agents. Besides liquid spray design, we also can offer you coating tank. This is used to mixing liquid coating materials evenly and send it to fertilizer drum coating machine with required speed.

How much is the fertilizer coating machine price?

The price of a fertilizer drum coating machine can vary significantly based on several factors. Including its size, capacity, and features.

Typically, the drum coating machine from YUSHUNXIN pricing range from $10,000 to $50,000. More advanced models equipped with additional functionalities, such as large capacity (20-40 t/h), precise control systems or the ability to handle multiple coating materials, may command higher prices, often exceeding $100,000. But, investing in a high-quality drum coating machine can yield significant returns by enhancing the performance of pelletized compost organic fertilizer products.

Is there automatic coating system for organic fertilizer making?

Of course. The YUSHUNXIN fertilizer coating machine is equipped with PLC control container.

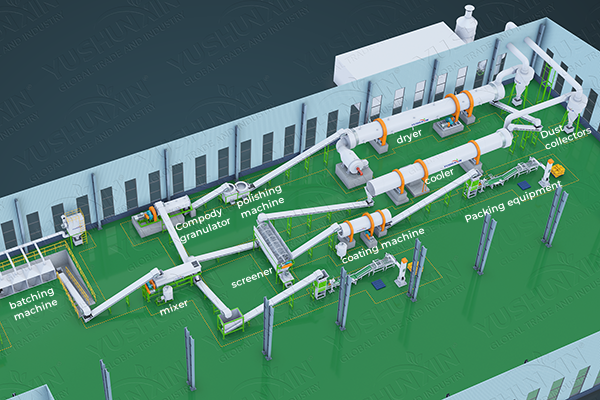

After setting required spraying volume, rotary speed, the system will automatically weight the spray materials and coating granulated organic fertilizer. It will work all the day for better commercial compost pellet making without worker operation. Besides, for those who want to setup a fertilizer coating system, YUSHUNXIN also can offer you customized controller combination. So, you can get an automatic fertilizer granule coating line, which consists of dryer, cooler, screener, coater and packing machine.

For better commercial compost pellets making, YUSHUNXIN also can offer you many other useful machines. Such as compost granulating machine, organic compost pellet dryer, fertilizer bagging system, etc. Welcome to contact us for your customized granulated compost solutions.

recently granulated compost solutions