How to recycle unqualified size particles for reprocess in compost granulation process?

In general, the rate of required size compost pellet making can reach 90%-95% with YUSHUNXIN compost pelleters. It can ensures minimal material loss. Still, to truly granulate compost in no waste, the remaining 5%-10% of granulated compost fertilizer—either too large or too small—must be properly recycled. Commonly, it needs only 2 steps.

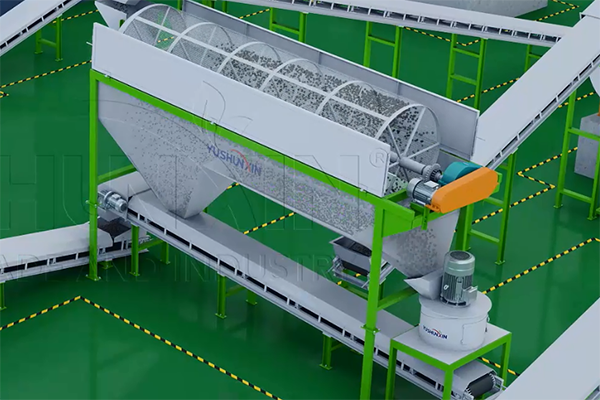

Separate compost granules with required size from the unqualified

First, you need to separate the granulated compost fertilizer pellets from those that do not meet your requirements. For this, rotary drum screener can finish it perfectly. With sieving mesh rotation, it can divide pelletized compost fertilizer into the size of required, too large and too small. There are 1-20 t/h capacity models of compost screeners for you.

Crushing returned fertilizer particles in fine powder

Next, you can grind the unqualified compost granules into fine powder for returning to the compost pellet making machine. For the returned compost pellets crushing the chain crusher is the best choice. Because of small space needed, you can put it closed to rotary screener directly. Namely, it don not need extra belt conveyor.

This system can greatly reduce the material waste in compost granulation plant. If you need the unqualified compost pellet recycling system, welcome to contact us now!

Is there powder dust material recycling system for no waste compost granulation?

Besides granulated compost fertilizer returning, you also can reach zero waste by prevent dust generation. For this, YUHSUNXIN can offer you best solutions, which contains:

Professional dust collectors

First, the most effective solution to recycle the spread powder in compost granulation is use professional dust collectors. Including cyclone dust collectors, water curtain dust collectors, and dust fall rooms. These devices capture airborne particles during compost pellet making, especially in the steps of compost drying and cooling. The compost material in the dust collecting system can be recycled to prepare granular compost fertilizer again.

Fertilizer machine with dust covers

In addition, for further reduce the waste in compost granulation, you can also add dust covers on machine where compost powder is easier to spread. Such as belt convey and screening. Here, YUSHUNXIN can offer you these customized machine to granulate compost in no waste.

In summary, it is entirely feasible to granulate compost in no waste. YUSHUNXIN can offer you the best solutions. Welcome to contact us for your own granulation compost fertilizer manufacturing plan immediately.

recently granulated compost solutions