Arriba 2 Soluciones para mezclar biocarbón con compost para producir gránulos de fertilizante.

Comúnmente, cuando planea producir fertilizante de biocarbón granular con mezcla de compost, hay 2 tecnologías que puedes elegir.

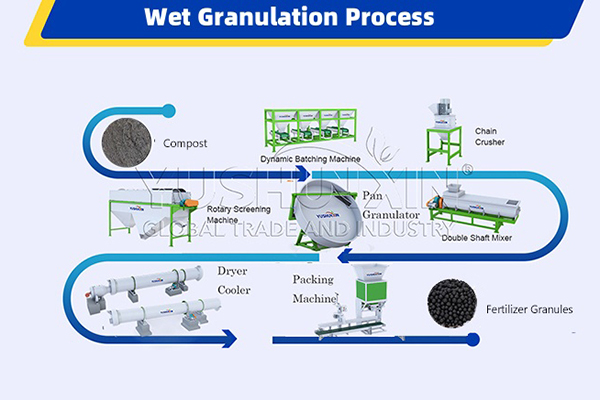

Línea de granulación de fertilizantes de biocarbón húmedo (20%–40% humedad)

Si su material de abono de biocarbón tiene una humedad de 20%-40%, comprar un línea de granulación de compost húmedo es una opción ideal. Porque puede utilizar líquido como aglutinante para facilitar la formación de fertilizantes a base de biocarbón a partir de compost.. Al mismo tiempo, Puede controlar fácilmente el tamaño del fertilizante de biocarbón granular en 1-8 mm mediante ajuste de humedad.

En general, Un sistema completo de granulación húmeda de mezcla de biocarbón y compost consiste en 9 etapas. procesamiento por lotes, aplastante, mezclando, granulación, cribado, el secado, enfriamiento, revestimiento y embalaje. Este sistema es adecuado para inversores que desean producir gránulos de fertilizante orgánico de biocarbón con apariencia de bola redonda y liberación lenta..

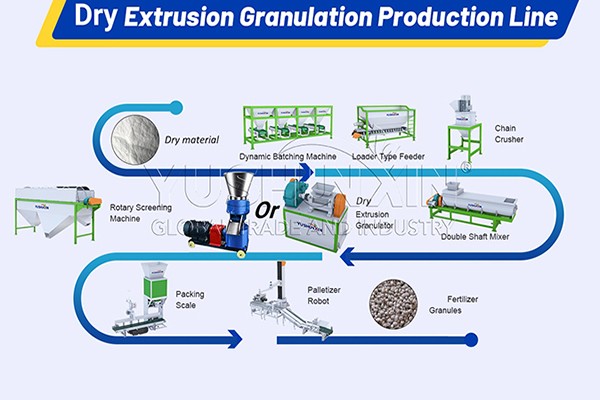

Granulación en seco de fertilizantes a base de carbón (bajo 20% humedad)

Sin embargo, si planea comenzar la producción de fertilizantes a base de abono biocarbón con material de abono con una humedad inferior a 20%, a sistema de granulación en seco es una mejor opción. Porque, Puede convertir el polvo de compost de biocarbón en gránulos de fertilizante orgánico sin necesidad de agua.. Respectivamente, Puede reducir el costo de compra de secadoras y refrigeradores., que se utiliza para secar fertilizantes granulados a base de carbono a niveles inferiores a 10% para facilitar su almacenamiento y transporte.

Por lo tanto, para la elaboración de fertilizantes a base de carbón con tecnología de granulación seca, solo necesitas comprar 7 maquinas. Son máquinas dosificadoras., muelas, licuadora, equipo de granulación, máquina de tamizado, máquina de recubrimiento y equipo de ensacado. Esta solución es ideal para pequeñas y medianas empresas que buscan producción de fertilizantes de biocarbón granular con costos operativos más bajos y un inicio más rápido..

Cómo comprar el granulador de fertilizantes a base de carbono adecuado para su proyecto?

Además de la humedad del material, También debe considerar qué tipo de gránulos de fertilizante a base de carbón se requieren.? Forma redonda u otras? Tamaño fijo o ajustable? alta dureza o no? Aquí, YUSHUNXIN ofrecerá varias máquinas granuladoras de fertilizantes para satisfacer plenamente sus necesidades de fabricación de fertilizantes biocarbón..

Granuladores de fertilizantes de biocarbón de forma redonda

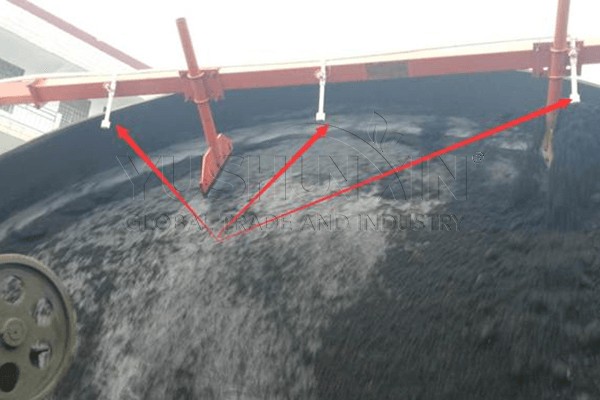

Cuando requiere granulación de fertilizantes con biocarbón y compost mezclados, La peletizadora de disco y el granulador de tambor giratorio son una excelente opción.. Negativamente, Es una operación más económica comprar un granulador de doble rodillo o una fábrica de pellets de matriz plana..

Fabricación de pellets de fertilizante a base de carbón ajustable de 1 a 8 mm

Considerar producir gránulos de fertilizantes a base de carbono en varios tamaños con el sistema en el futuro, Es recomendable comprar un granulador de plato o un equipo de granulación de tambor.. Puede regular la producción de fertilizantes de compost a base de biocarbón granular en 1-8 Tamaño mm libremente. Sólo mediante control de humedad del material., en lugar de reemplazo de piezas.

Producción de gránulos de fertilizantes a base de carbono duro

Entonces, si tiene requisitos especiales sobre la dureza del fertilizante de biocarbón granular que produce, Puedes elegir libremente el nuevo tipo de granulador de fertilizante orgánico., peletizadora de matriz plana y extrusión de rodillos. Bajo la acción de la presión mecánica., hay una alta dureza de 15-20 N en su fertilizante carbonizado granulado.

| Equipo | Capacidad (t/h) | Tamaño de gránulo (milímetros) | Tasa de granulación | Humedad del alimento | Forma final |

|---|---|---|---|---|---|

|

Granulador de tambor rotatorio |

1-30 | 3-6 | 90% | 20%-40% | bola redonda |

|

Peletizadora de disco |

1-6 |

1-8 | 93% | 20%-40% | bola redonda |

| Granulador de rodillos | 1-4 | 3-10 | 95% | <20% | bola plana |

| Molino de pellets plano | 1-2.5 | 3-10 | 95% | <20% | cilíndrico |

| Peletizadora de dientes agitadores | 1-8 | 2-5 | 95% | 20%-40% | bola redonda |

¿Cuál es la cotización de la línea de producción de fertilizantes a base de biocarbón granular YUSHUNXIN??

El rango de precios de una línea de producción de fertilizantes a base de biocarbón granulado suele abarcar desde $50,000 a $500,000. Esto depende principalmente de la configuración.. YUSHUNXIN ofrecerá su solución personalizada para mezclar biocarbón con compost para la fabricación de pellets de fertilizantes..

$60,000-$150,000 solución para hacer gránulos de compost de biocarbón

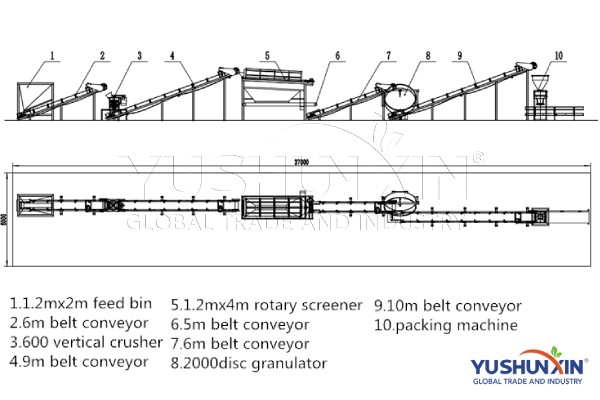

Una línea de producción básica para fabricar gránulos de fertilizantes de carbono a partir de compost, que normalmente tiene un precio de alrededor de $60,000-$150,000. Suele incluir maquinaria esencial para fertilizantes biocahr como una trituradora., mezclador, equipo granulador y envasador. Estas configuraciones son adecuadas para 1-10 t/h operaciones de granulación de compost de biocarbón que requieren un enfoque práctico.

$150,000 y $300,000 Fabricación de fertilizantes granulados a base de carbón

A medida que la complejidad del equipo de granulación de fertilizantes a base de carbono, cuestan entre $150,000 y $300,000. Aquí, El sistema contiene las máquinas granuladoras de compost de biocarbón desde la trituradora hasta la báscula de embalaje.. Al mismo tiempo, También puede cumplir plenamente con sus requisitos para 1-10 t/h de producción de fertilizante granulado a base de carbón.

$300,000-$500,000 Costos de producir pellets de fertilizantes de biocarbón a partir de compost.

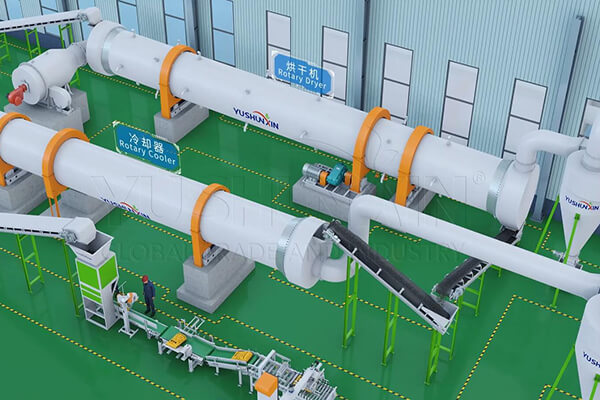

Si estás preparando un $300,000-$500,000 presupuesto, Puede comprar un sistema de abono de biocarbón a gránulos de fertilizante con total automatización.. Está especialmente diseñado para la granulación de fertilizantes a base de carbono a gran escala con 10-20 Capacidad de TPH. Esto también consta de todo el conjunto de máquinas granuladoras de compost, incluida la máquina paletizadora.. Casi no se necesita mano de obra y puedes ganar más dinero.

¿Puede ofrecer una planta de granulación de fertilizantes de biocarbón terminada como referencia??

Absolutamente, como fabricante profesional de equipos de fertilizantes y proveedor de soluciones, YUSHUNXIN había ayudado a inversores de 100+ Países inician con éxito sus proyectos de granulación de compost de biocarbón. El último se encuentra en Malasia.. es un 20,000 Sistema de granulación de compost y biocarbón MT. Bienvenido a contactarnos para obtener su propia solución de producción de fertilizantes a base de carbono ahora.!

¿Existen máquinas para producir biocarbón y compost para la fabricación de fertilizantes a base de carbón??

Por supuesto. Como fabricante considerado de equipos para la fabricación de fertilizantes de compost granulado., Podemos proporcionarle máquinas de biocarbón y equipos de compostaje de calidad..

Por otro lado, con máquina de compostaje de fertilizantes profesional, puedes terminarlo dentro 20 días. Para esto, Hay compostadores en recipiente para una preparación rápida del compost., volteador de compost tipo rueda a gran escala, máquina de compostaje económica tipo ranura, etc..

¿Podemos integrarnos en la eliminación de dióxido de carbono? (CDR) mercado con el sistema de fertilizantes de biocarbón?

¿Podemos integrarnos en Eliminación de dióxido de carbono (CDR) mercado con el sistema de fertilizantes de biocarbón?

Es beneficioso no sólo para la reducción de carbono de la eliminación de residuos de biomasa, sino también el secuestro de carbono y la obtención de créditos de carbono mediante la producción de biocarbón y fertilizantes a base de carbono..

En general, 1 tonelada de biocarbón = 3 toneladas de eliminación de residuos de biomasa = 2,0–2,4 toneladas de CO₂ eliminadas. Y puede generar un flujo de ingresos adicional a través de créditos de carbono valorados entre 200 y 400 euros por tonelada de CO₂..

¿Puede ofrecer un proyecto reciente de fabricación de fertilizantes de biocarbón para CDR como referencia?? Por supuesto. Por ejemplo, el Solución llave en mano para proyecto CDR forestal en Canadá, etc..

Además de la producción de fertilizantes a base de biocarbón granulado, YUSHUNXIN también puede ofrecerle muchas otras soluciones para la fabricación de pellets de compost.. Como plan de granulación de fertilizantes de biocompost, Línea de granulación de compost de estiércol de vaca, Proyecto de fabricación de pellets de estiércol de pollo fermentado., etc.. Bienvenido a contactarnos para obtener el mejor de inmediato..

soluciones de compost recién granuladas