What is the process to make slow release fertilizer pellets from compost?

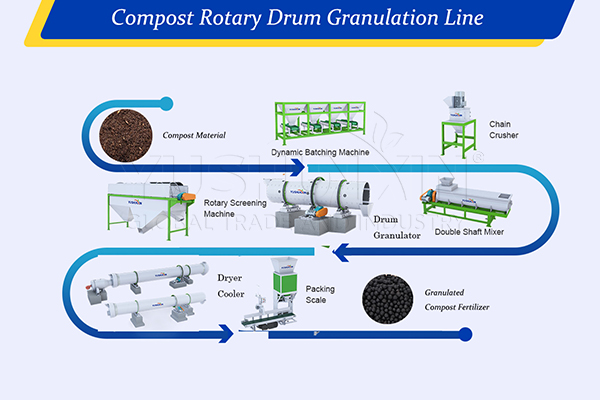

In general, preparing compost fertilizer granules with slow releasec performance contains 5 parts.

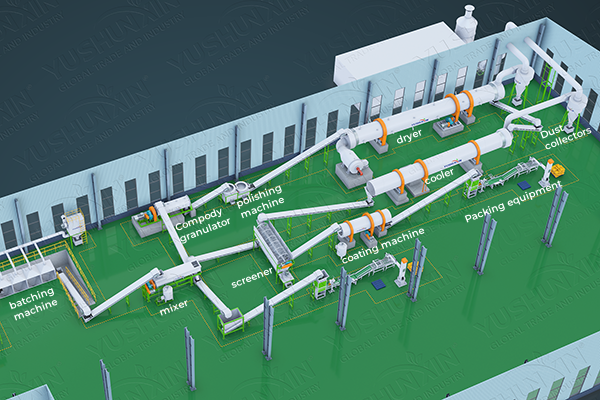

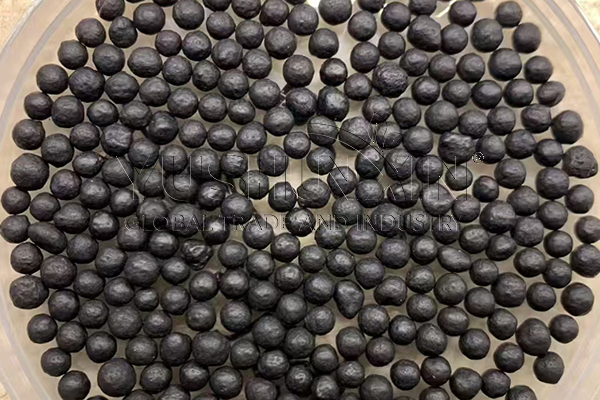

In sum up, the whole system to make slow release fertilizer pellets from compost consists 8 equipment. Batching machine, compost grinder, mixer, pelletizer, dryer, cooler, coating machine and bagging equipment. These pelletized organic compost fertilizer, when applied to soil, gradually release nutrients, supporting plant growth over an extended period.

how to add Slow-Release Agents when make slow release fertilizer pellets from compost?

To incorporate slow-release functionality with your granular compost fertilizer, there are 2 ways for your choice.

Mixing before slow-release fertilizer granulation

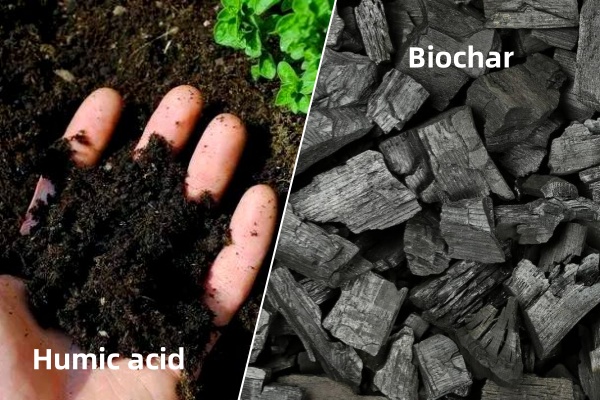

For one thing, you can blend the slow-release additives into the compost material before granulation. After the compost is crushed and screened, the additives (humic acid, biochar, etc.) and binders are mixed uniformly in a horizontal or vertical compost mixer. This ensures even distribution and consistent performance in the final product.

Adding slow release agent during compost pelleting

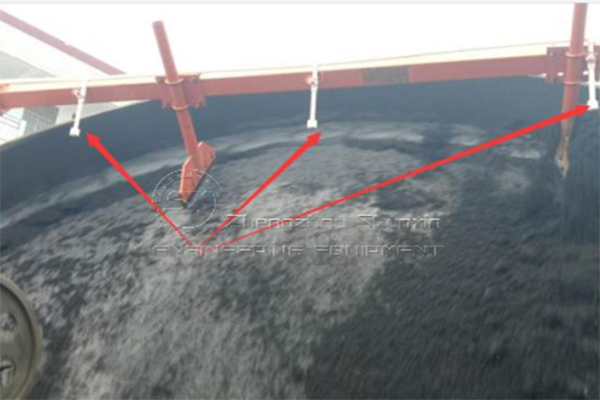

In addition, there are also compost pellet machines with spray device. Including a rotary drum granulator and disc pelletizer. They can add slow-release agent while compost granulation. This is suitable for thoese who only need a slow release fertilizer granulator.

Coating slow release agent film

For another, you also can choose to use a rotary drum coater to apply external layers that slow the nutrient release after pelletizing by a compost granulation equipment. If you plan to process the granulated compost fertilizer into slow-release, this method is recommended.

How long does it take for fertilizer to slow release?

Slow-release fertilizers made from compost typically begin to work within three to ten weeks, as microorganisms break down the nutrients slowly. This gradual process ensures that plants receive a consistent supply of essential nutrients over time. Some slow-release fertilizers can continue to be effective for a few months, and in some cases, up to a year, providing long-term nourishment and reducing the frequency of reapplication. This makes them ideal for maintaining healthy plant growth with minimal effort. So, there are many fertilizer manufacturers investing in project to make slow release fertilizer pellets from compost.

If you want to know more about granulated compost manufacturing solutions and machine, welcome to contact us immediately. There are compost granulation plans range from 1 t/h operation to 20 t/h ouput, from cow dung pelleting to mineral waste compost granulation, etc for your choice.

Content

- ¿Cuál es el proceso para elaborar pellets de fertilizante de liberación lenta a partir de compost??

- ¿Qué material se puede utilizar para la fabricación de gránulos de fertilizante de liberación lenta??

- cómo agregar agentes de liberación lenta al hacer gránulos de fertilizante de liberación lenta a partir de compost?

- ¿Cuánto tiempo tarda el fertilizante en liberarse lentamente??

recently granulated compost solutions