How to finish Rhizobium biofertilizer granules making from compost?

The Canadian customer’s most important requirement for biofertilizer granulation from compost is to preserve rhizobium biological content. Para esto, hay 2 solutions for your.

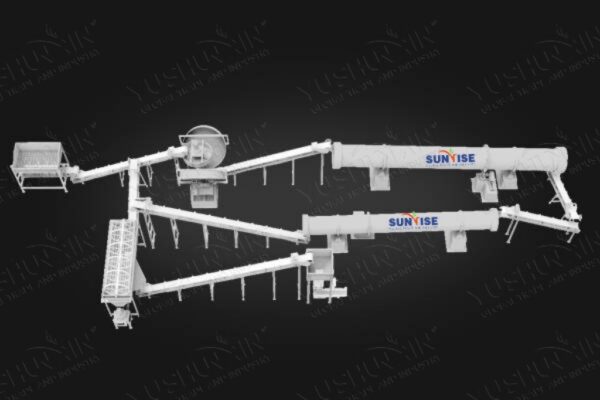

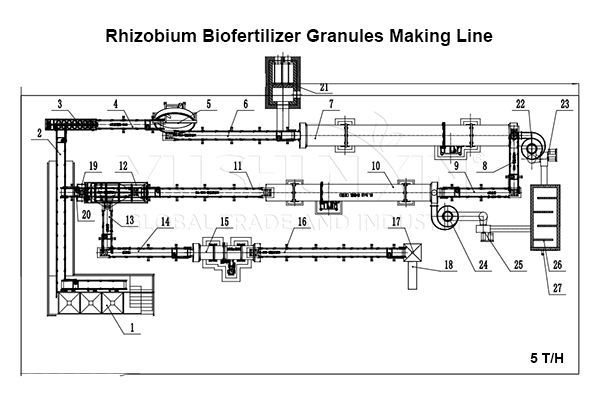

After consideration, the customer from Canada chose the coating method for the rhizobium biofertilizer granules making. Entonces, the whole process contains 8 regiones. Including batching machine, SXFLF-600 vertical crusher, mezclador de doble eje, SXYZ-3600 disc pelletizer, SXGS-1540 rotary screener, SXHG-1616 rotary dryer and cooler, rotary coating equipment and single bucket packing scale. En general, this system can fully meet your requirements of 5 t/h granular biofertilizer making from compost. Namely, 20,000-30,000 tons annual output.

Can it produce Rhizobium bio fertilizer into 2-5 mm spherical granules?

Por supuesto. The pan biofertilizer granulation line can fully meet your needs of round ball compost pellet making en 2-5 milímetros.

El disc granulation system can process compost into spherical rhizobium biofertilizer pellets easily. Because the pan pellet machine is granulating compost powder by disc rotation. Which makes material roll and combine into round ball fertilizer.

As for size of final bulk density bio fertilizer pellets, you can adjust between 1-8 mm according to your needs. It only need to regulate the disc slope and moisture content. The sharper the slope, cuanto menor sea el tamaño, the slower the slope, cuanto mayor sea el tamaño. The less the water the smaller the size, the more the water, cuanto mayor sea el tamaño.

How to control bio fertilizer pellets bulk density to 650 a 800 kg/m³?

Then for the bulk density of granulated biofertilizer compost, the Canadian client required between 650 y 800 kg/m³. Is this requirement achievable? La respuesta es si. You can improve the bulk density of your biofertilizer pellets by 2 ways.

Simply, you can mix compost with high density materials before rhizobium biofertilizer granules making. Such as Ammonium sulfate, monoammonium phosphate, bentonite, kaolin, etc.. And the recommended proportion is 5%-10%.

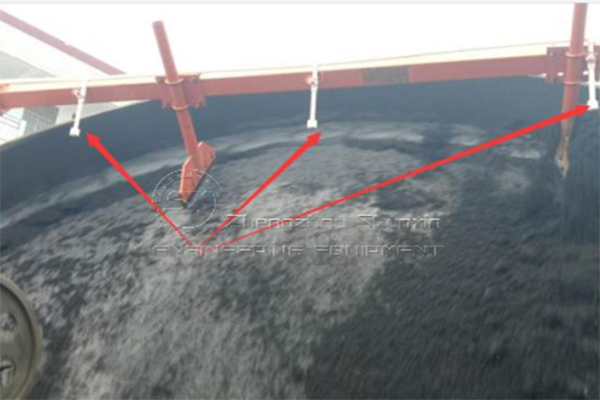

Además, it is also an ideal choice to add appropriate amount of liquid binders during rhizobium fertilizer granulation. Such as molasses, sodium alginate, etc.. Aquí, the best moisture content is 20%-30%. Aquí, the spray device on disc pellet machine can help you control the liquid adding volume precisely.

Is granulated biofertilizer supporting blending with standard fertilizer pellet in a large scale?

Absolutamente. If you want to enlarge your market by blending granular rhizobium biofertilizer pellets with NPK fertilizers, it is completed easily.

Only to control the granule size to 2.5-5 mm and density to 650–800 kg/m³. Aquí, the disc granulation line can fully meet your requirements. Además, the coating equipment can help you improve the fertilizer hardness to ≥10 N by adding bentonite, kaolin clay, PLA, melaza, etc.. Entonces, it is not easy to break during the fertilizer pellets bulk blending. Entonces, como un professional fertilizer equipment manufacturer, we also can offer you quality granule blending systems, which has a high precision and 5-40 t/h capacity range.

De este modo, you can produce both rhizobium biofertilizer granules fertilizers to local leguminous crops farmers and complex fertilizer to cover wider market.

The above are details about our communication with the customer about rhizobium biofertilizer granules making in Canada. Además, if you get our own bio fertilizer granulation solution or other compost pellet making systems, welcome to contact us now! There are also chicken manure compost granulation line, biogas digestate fertilizer pellet plan, biochar compost granule production project design, etc..

Contenido

- Comment finir les granulés de biofertilisant Rhizobium fabriqués à partir de compost?

- Peut-il produire du bio-engrais Rhizobium dans 2-5 granulés sphériques mm?

- Comment contrôler la densité apparente des granulés de bioengrais pour 650 à 800 kg/m³?

- Le biofertilisant granulé permet-il le mélange à grande échelle avec des granulés d'engrais standard?

More Cases